- Quality Management

Home » Free Resources » »

Five Phases of Lean Six Sigma: A Complete Guide

- Written by Contributing Writer

- Updated on March 21, 2023

Customer expectations and behavior are constantly changing. Competition in nearly every industry seems to be intensifying. Profitability and growth now depend in large part on the efficiency of products and services and their speed to market.

Six Sigma is a process that organizations employ to optimize business processes for the most efficient and cost-effective approach while producing continuous product improvements.

In this article, we’ll explain the Six Sigma methodology, explore its benefits and challenges, and detail the five phases of Lean Six Sigma with examples.

What is the Six Sigma Methodology?

The Six Sigma methodology identifies defects and roadblocks that hinder performance, enabling companies to use strategies to streamline processes, decrease production variation, and improve the quality of products and services.

Six Sigma is a data-driven approach to establishing a culture committed to continuous process improvement. When implemented effectively and consistently, Six Sigma provides a framework for repeatable and systematic problem-solving.

Also Read: Six Sigma Methodologies for Process Improvement

What Is the Difference Between Six Sigma and Lean Six Sigma?

Six Sigma focuses on creating rigid consistency to reduce process variation and enhance process control. Lean Six Sigma eliminates processes that do not add value to promote more streamlined workflows.

In short, Six Sigma emphasizes reduction in variation using processes such as:

- Statistical data analysis

- Design of experiments

- Hypothesis testing

Lean Six Sigma focuses on reductions in waste using processes such as:

- Workplace organization

- Visual controls

In most cases, organizations today incorporate both methodologies into their Six Sigma quality management practices.

What Are the Benefits of Six Sigma?

The benefits of Six Sigma and the DMAIC process include:

Improvements in Quality

By focusing on identifying and eliminating defects and wasted steps in processes, organizations can improve the quality of operations and products or services.

Increases in Efficiency

Six Sigma identifies roadblocks and inefficiencies in systems. Efficiency and productivity gains provide significant results in many cases. In manufacturing, for example, these efficiencies can improve quality, turnaround times, and cycle times for equipment.

More Efficient Decision Making

By putting quantifiable data at the heart of decisions, organizations can reduce making decisions based on intuition or assumptions. Instead, decisions are made based on facts and evidence and are measured against baselines for continuous improvement.

Improved Customer or End-User Satisfaction

When organizations can streamline processes to produce faster or higher-quality results, it improves customer satisfaction. This, in turn, can generate more loyal customers and higher customer retention levels.

Cost Savings

There can be significant financial benefits from implementing a Six Sigma methodology. Increased efficiency reduces waste and defects, creates efficiencies and streamlines processes, and produces better customer satisfaction.

Competitive Advantage

Organizations that utilize the five phases of Lean Six Sigma methodology can gain a competitive advantage in several ways, including delivering higher-quality products or services more efficiently and cost-effectively than their competitors.

Employee Engagement

Not to be overlooked in the five phases of Six Sigma are the benefits to employee engagement. Project teams typically include employees from various disciplines. Working together to understand problems and develop solutions encourages teamwork and is fundamental to creating a culture of continuous improvement.

Involving team members in the process also creates buy-in since team members have a stake in the success of the Six Sigma process.

Also Read: Six Sigma Principles: A Comprehensive Guide to Implementing and Optimizing Your Processes

What is DMAIC?

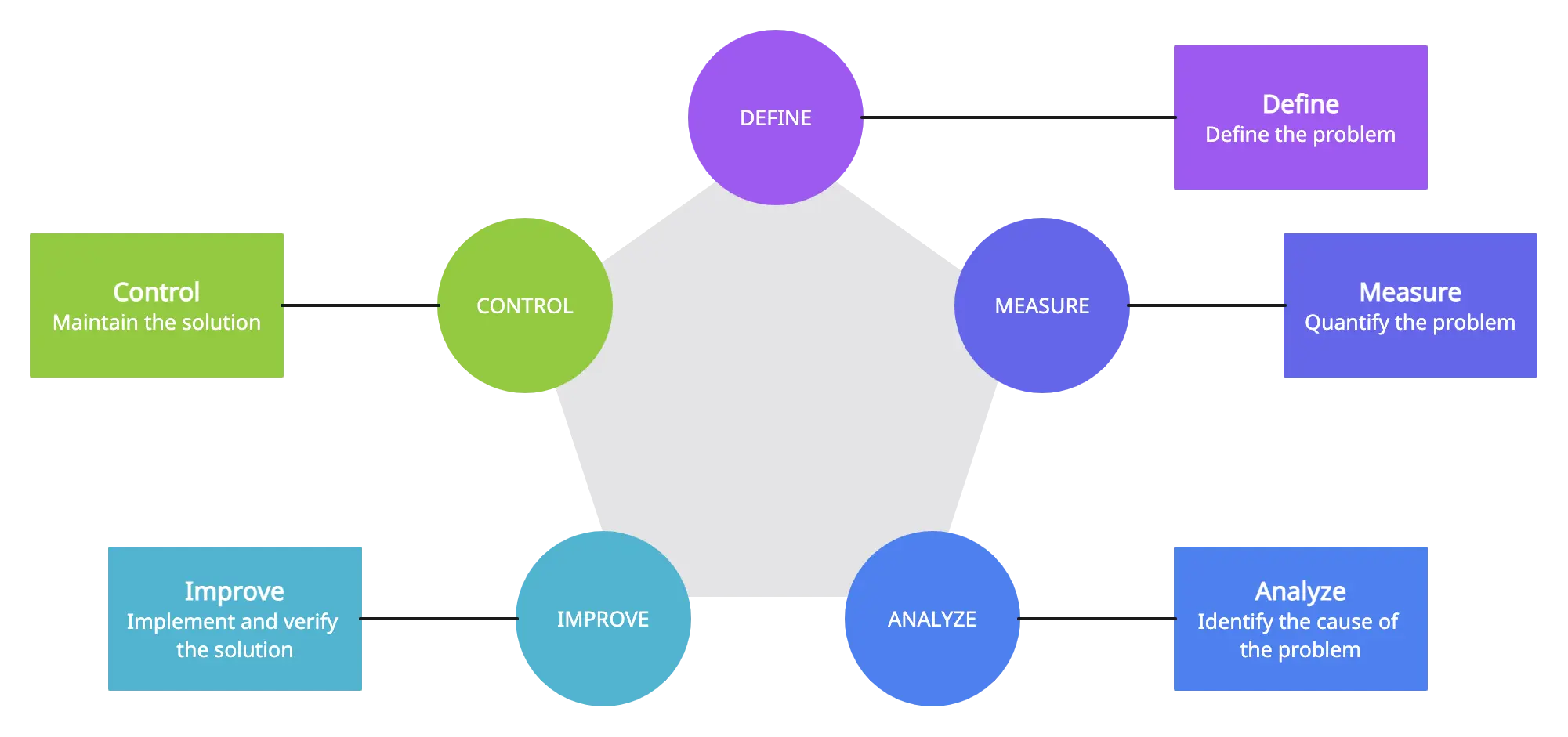

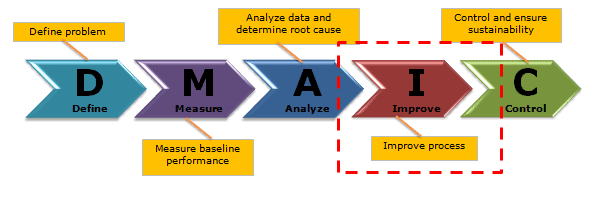

DMAIC is an acronym for the five phases of Six Sigma.

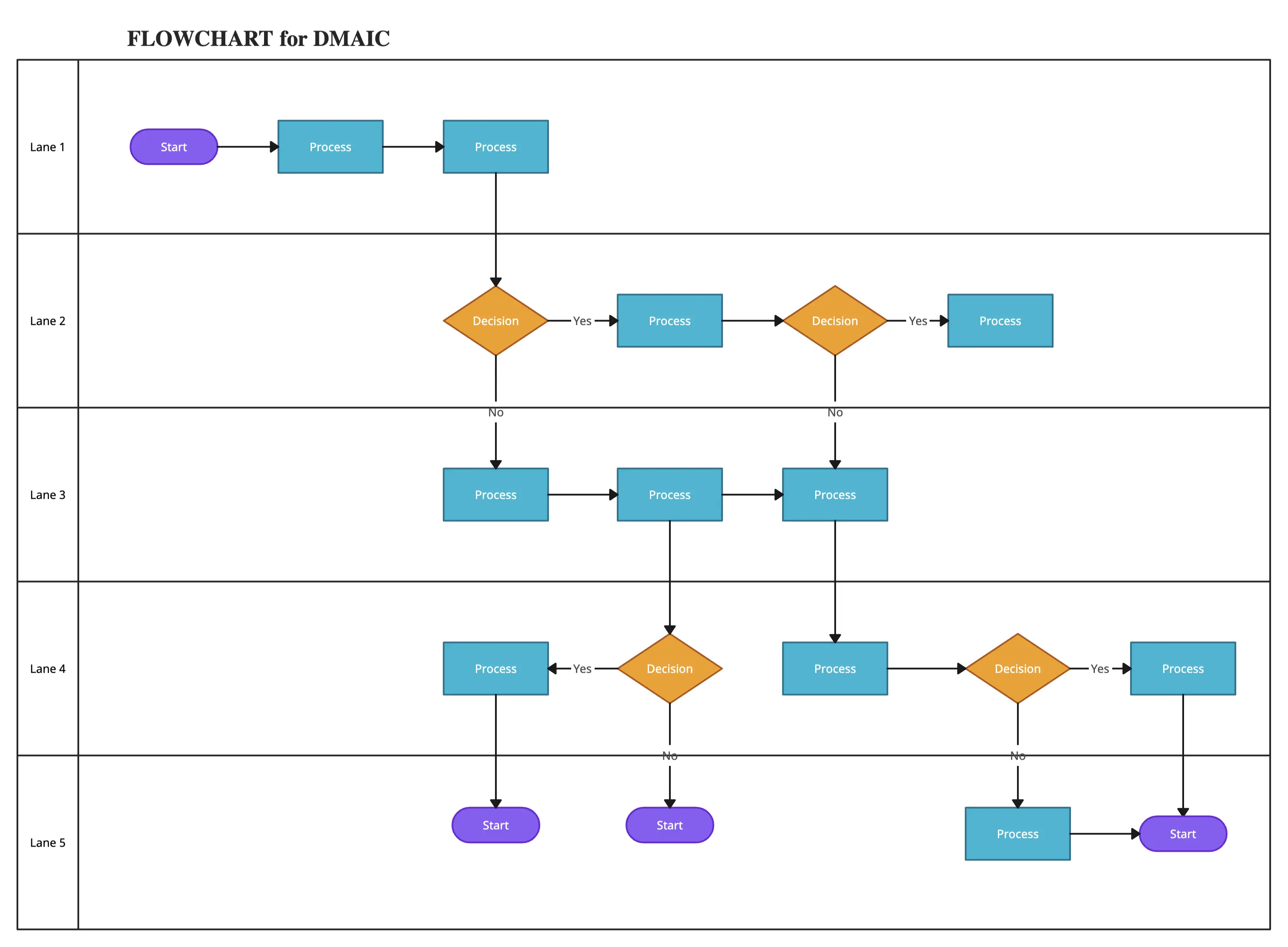

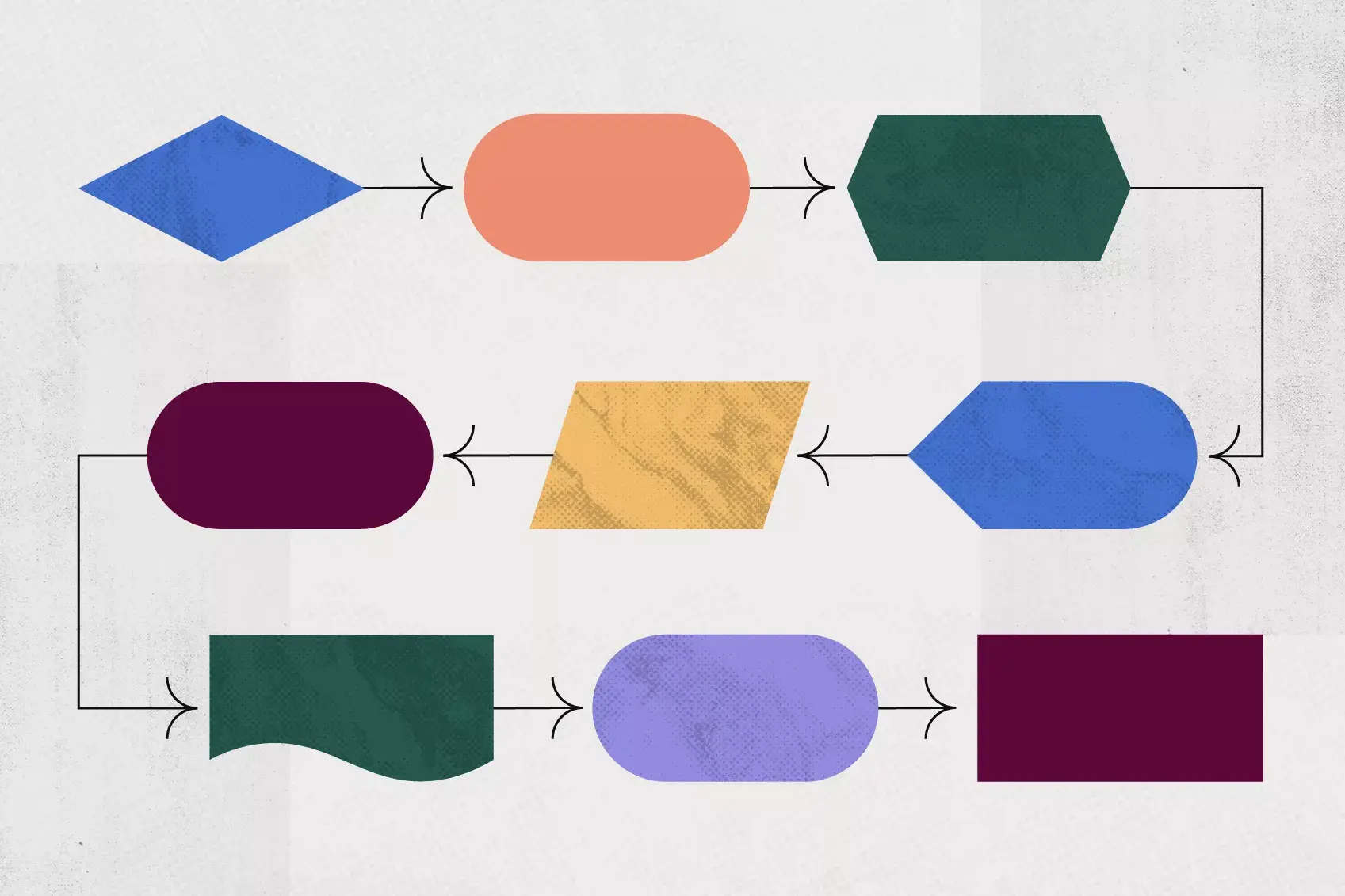

The DMAIC phases are an iterative process used to seek quality improvement by focusing on the process to create more efficient and permanent solutions. DMAIC provides the structure to the process, enabling project teams to use specific tools and deliverables that lead to process improvements. While most teams work through DMAIC in a linear fashion, it isn’t mandatory to do it this way. The process itself encourages team members to backtrack to previous steps, especially when additional information or insight is needed.

The Five Phases of Lean Six Sigma

Each of the five phases of Six Sigma is data-driven and focuses on standardizing an organization’s approach to problem-solving. So, let’s dig deeper into the DMAIC phases.

Phase 1: Define

In the define stage, team members work together to identify the information they’ll need to break down components of a problem or process and create smaller actionable terms. Rather than focusing on abstract goals, it seeks quantifiable and qualifiable data to clearly identify the objective of the project.

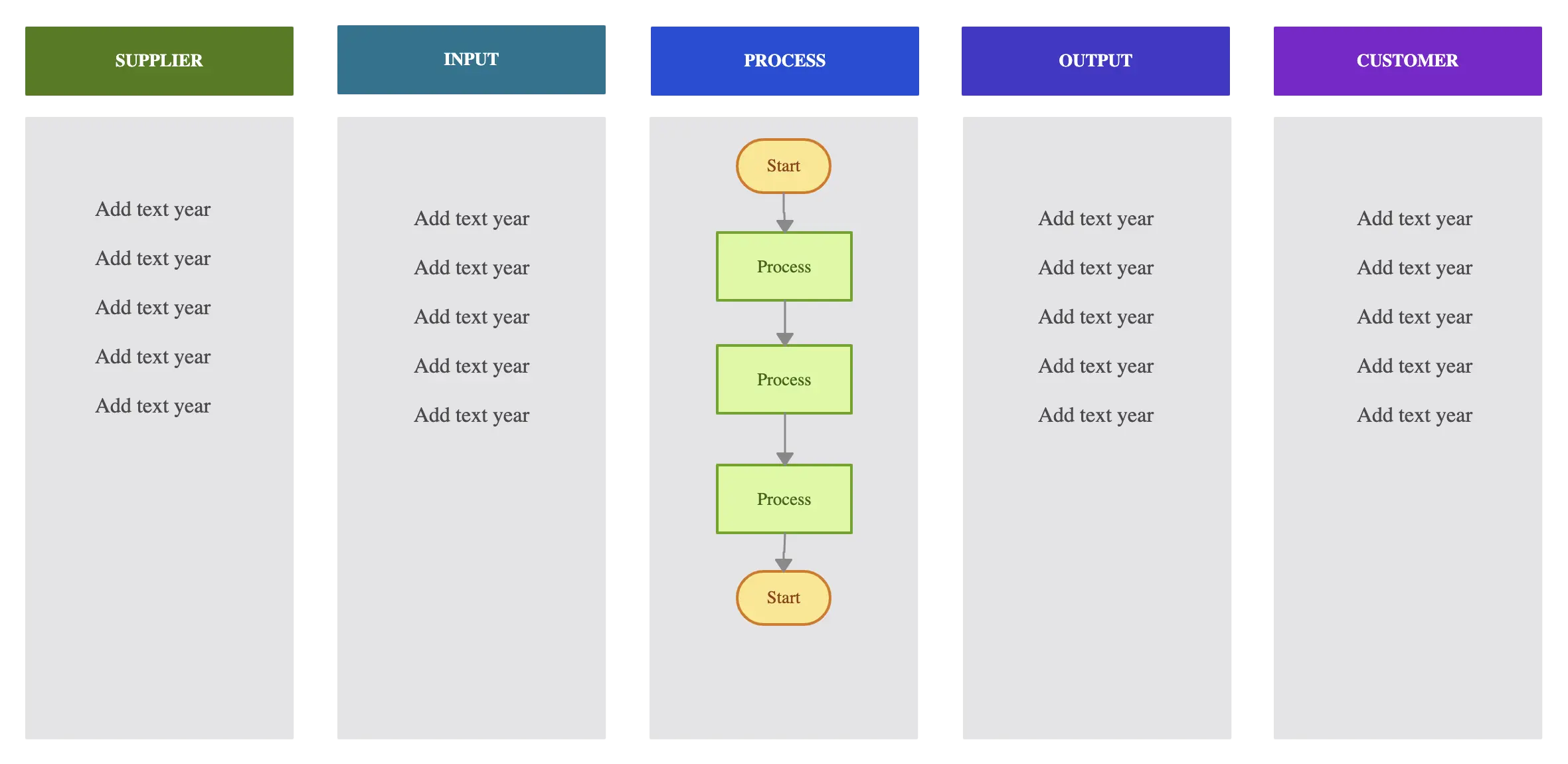

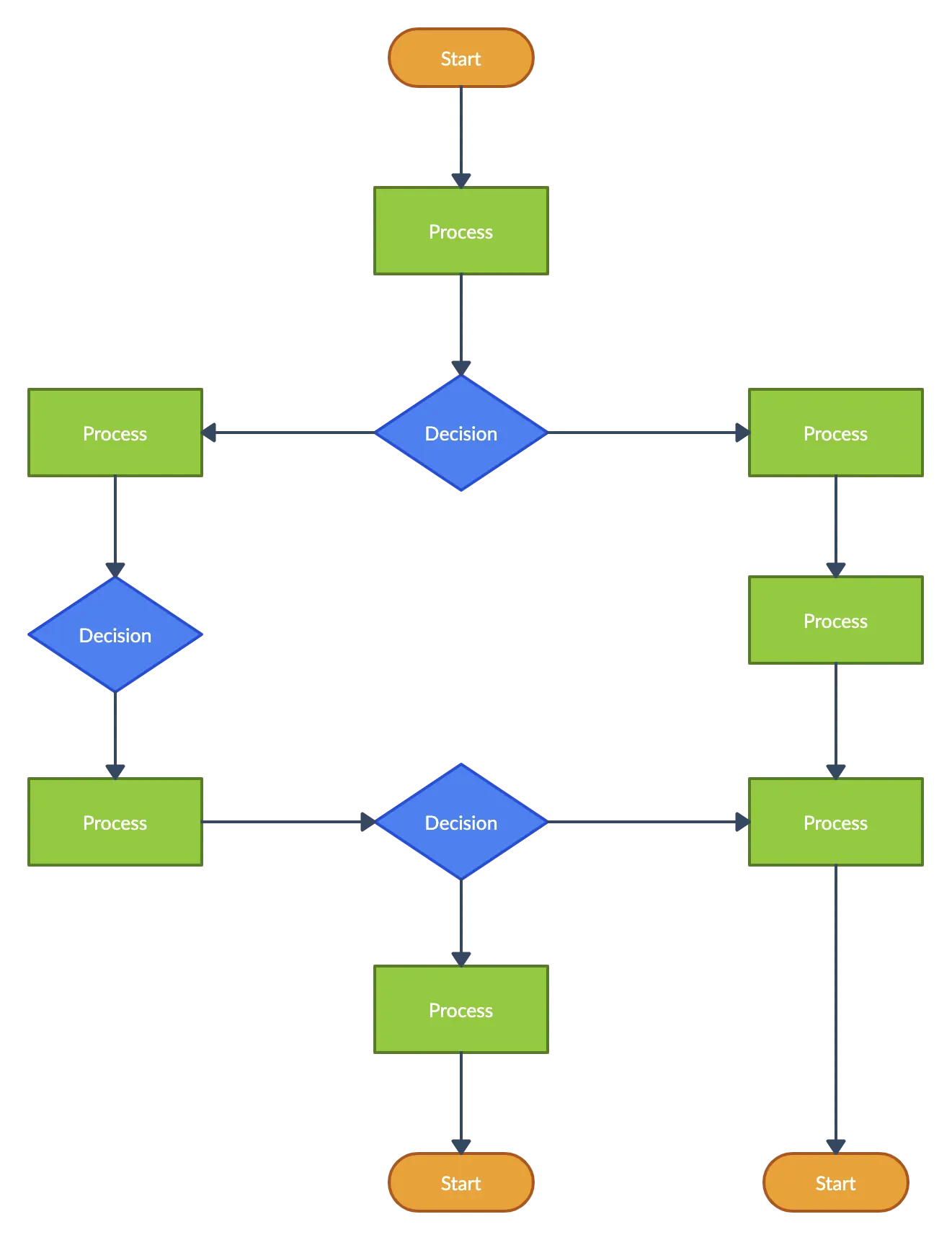

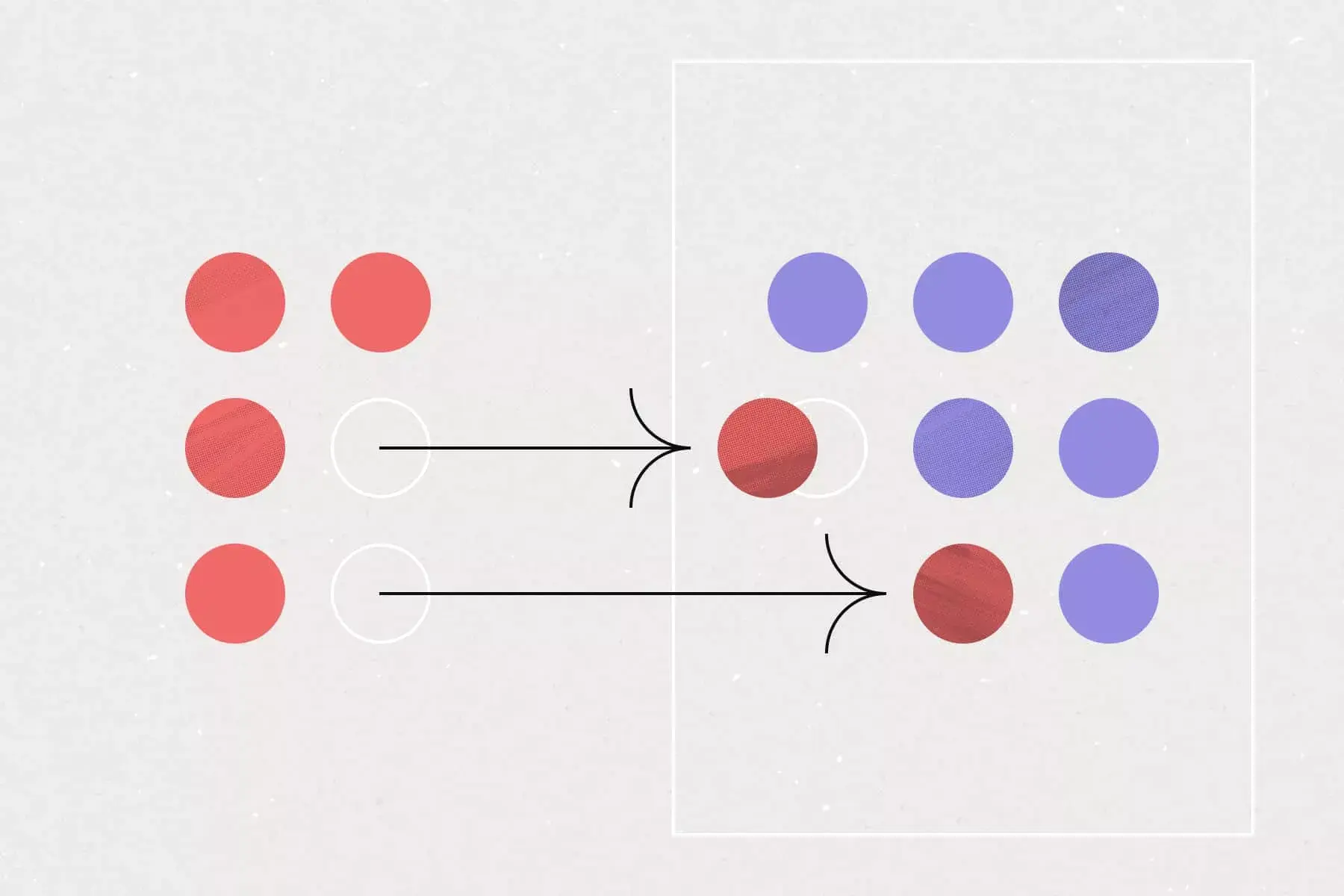

Teams will identify the Critical to Quality (CTQ) attributes as determined by the end-user or customer — called the voice of the customer (VOC) — and create a process map, including process inputs and process outputs.

For example, a manufacturing company has identified a problem somewhere in their production process that is leading to product defects outside of acceptable ranges but doesn’t know where or why these defects occur. In the define phase, they would design the project scope and establish objectives, such as reducing the number of acceptable defects in the production process to a specific number.

Phase 2: Measure

The measure step of the DMAIC phases of the Six Sigma process assesses current processes and capabilities. While the goal is to make process improvements, teams need a clear understanding of the current conditions to judge the effectiveness of any future changes. Without a baseline, it’s hard to measure if you’ve made any progress.

In this phase, team members will measure the current process and create a baseline for future comparison.

For example, this phase would identify the frequency of the defects and information about potential causes, such as production line speed or equipment breakdowns, deviations in material or suppliers, or other mitigating factors.

Phase 3: Analyze

The analysis phase of the Six Sigma methodology takes a deep dive into the data that’s been gathered to isolate root causes of inefficiencies and identify defects. Teams in this phase often create detailed subprocess maps for every step with the goal of eliminating and streamlining steps to improve performance and quality.

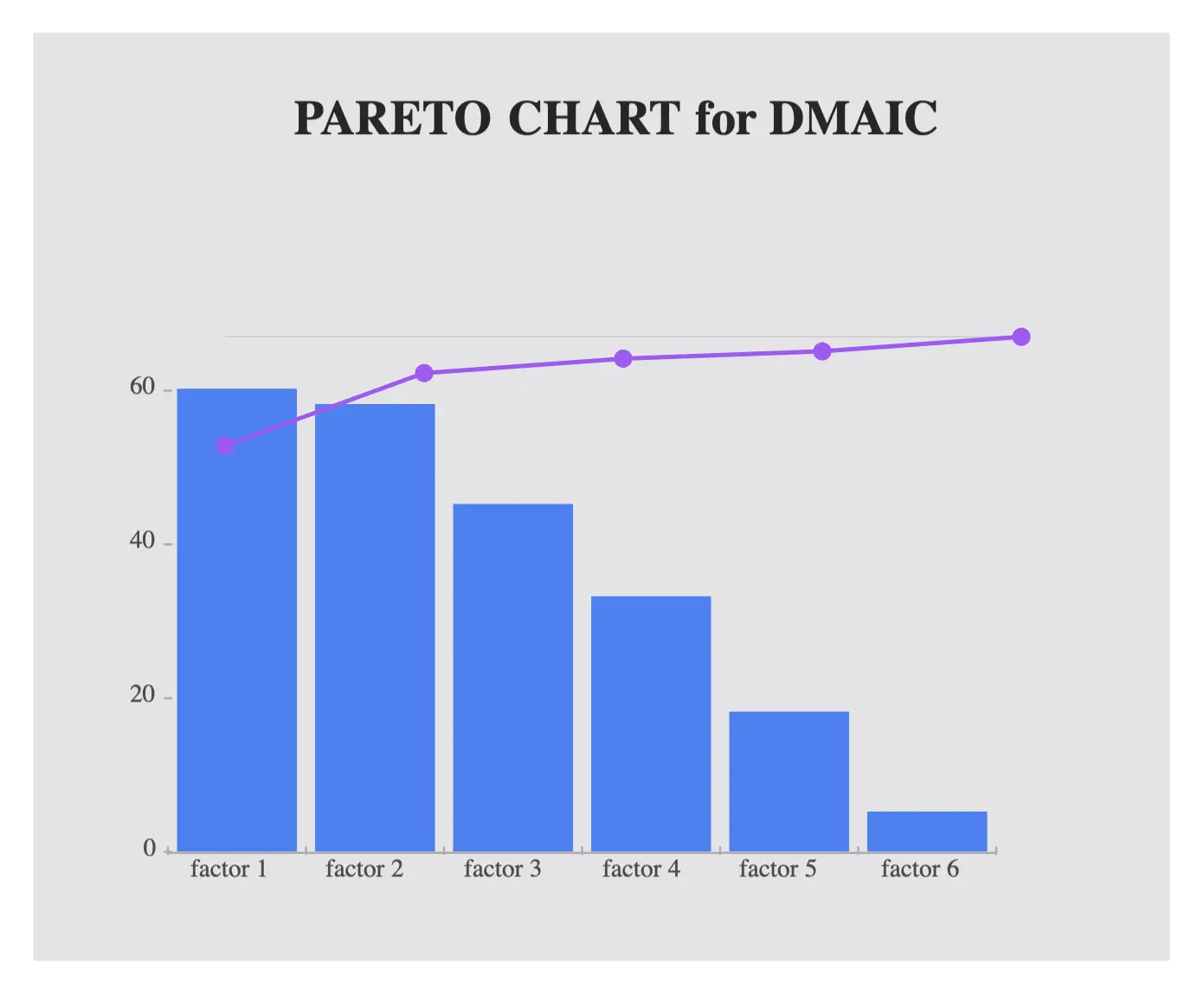

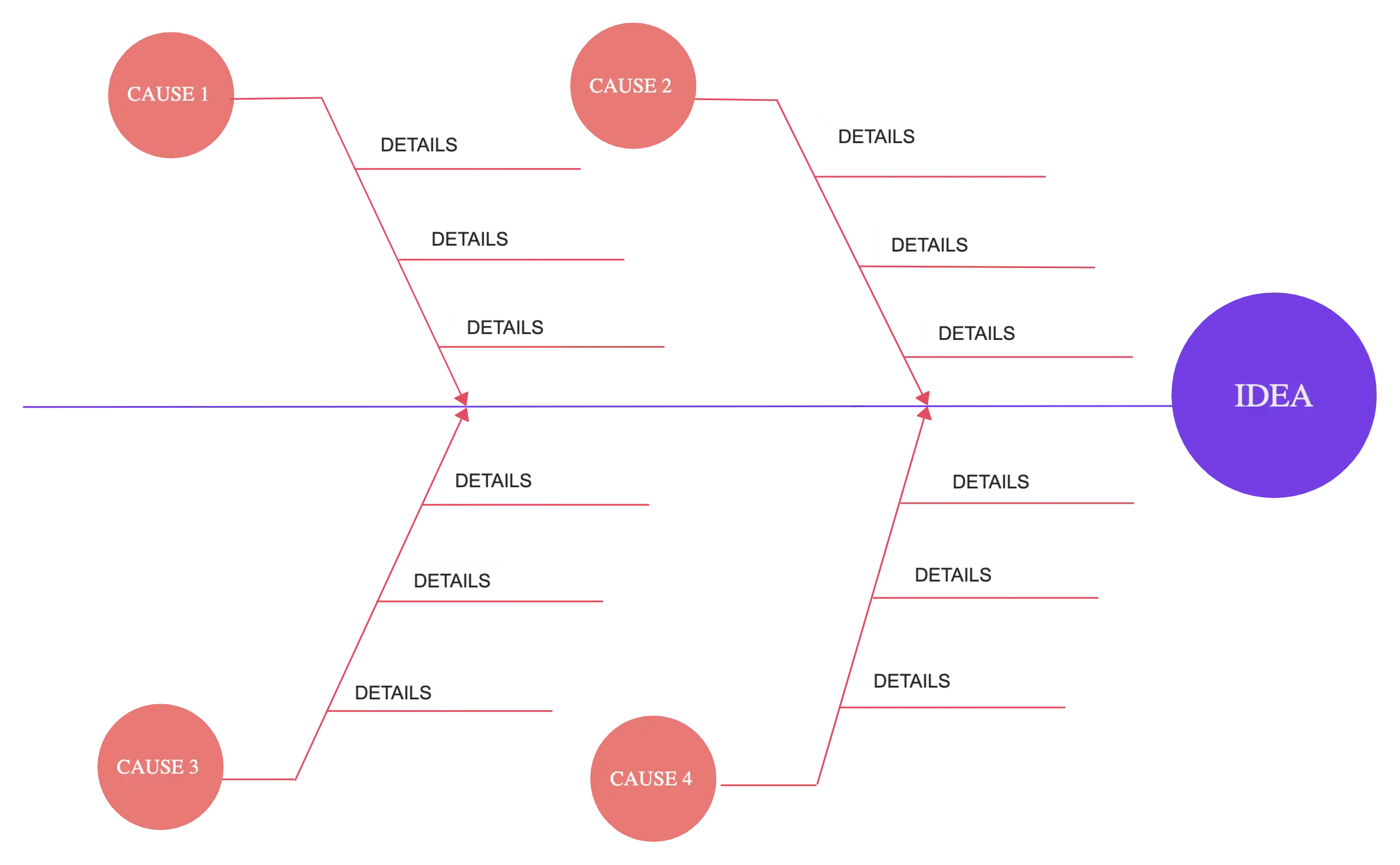

Teams might deploy several analysis tools, such as Pareto charts or fishbone diagrams, to analyze the root causes of the high defect rate.

Teams also analyze the performance and financial benefits of solving a problem or improving a process.

Phase 4: Improve

After identifying the root cause of any issues, this phase focuses on finding the solution or improvement. Common methods include deploying a design of experiment model to isolate variables and test hypotheses until obstacles are uncovered.

Once process improvements are identified, teams create a proposed solution and then implement pilot programs to test, ensuring solutions meet project objectives and are financially viable.

As an outcome of analyzing the data, teams might redesign the production process, recommend upgrading equipment or maintenance procedures, or provide additional training to operators.

Phase 5: Control

The final step of the five phases of Lean Six Sigma involves documentation of the solutions created for process owners. This includes actionable steps, timelines, and milestones for implementation. In this phase, the control plan details the daily workflow.

The project team then monitors the project for a prescribed period to make sure the process meets performance expectations in real-world environments before turning it over to process owners.

In the control phase, organizations might implement control charts to tightly monitor production output and defect rates, the impact of operator training, and any other solutions deployed.

Each of the five phases of Six Sigma works together to create a repeatable template for improving business processes. When fully integrated into an organization’s culture, it enables teams to innovate new solutions, measure effectiveness and efficiency, and create quantifiable process improvements.

Also Read: Six Sigma vs. Lean Six Sigma: Which Methodology Is Right for Your Business?

Challenges with Implementing Six Sigma

Even though Six Sigma can help your team become more efficient and cost-effective, there are implementation challenges when it comes to DMAIC phases.

The five phases of Lean Six Sigma examine increasingly minute details and micro-steps in every aspect of task completion. This can be challenging for team members to accomplish without experienced project managers that are trained in Six Sigma methodologies. Organizations need team members that understand statistical training and quantifying data points effectively in order to successfully implement this methodology — it’s not something you can pick up on the fly.

Implementing Six Sigma Tools

There’s also a learning curve for the diverse set of tools required to uncover root causes and validate potential solutions. Throughout the DMAIC process, teams may need to be proficient in using tools such as:

- Pareto charts

- Gage R&R

- Process capability upper and lower bounds

- Attribute agreement analysis

- ANOVA statistical modeling

- Regression equations

- Control charts

- Statistical process control (SPC)

- Value stream mapping

Other tools may also be needed depending on industry and functionality. As you can see, some of these tools are incredibly specific and scientific, so it can be tricky to implement if someone on your team isn’t familiar enough with them while going through the five phases of Lean Six Sigma

Organizational Commitment

Effective Six Sigma implementation required buy-in across the wider organization, starting at the very top. Without proper funding, resources, and continued support, the process can be ineffective. In some cases, this leads to incomplete solutions, lack of follow-through, or failure to embrace workplace changes.

To be successful, Six Sigma needs to be embraced and become part of the company culture.

Also Read: Value Stream Mapping in Six Sigma

Fast Track Your Career in Quality Management

Efficiently deploying Six Sigma methodologies and DMAIC phases requires training and expertise. Professionally-trained and certified Six Sigma professionals can make substantive contributions to organizational improvement and earn a lucrative career as a Six Sigma expert.

If you are looking to fast-track your career in Quality Management, an accredited Six Sigma course can help. You can get hands-on experience and mentoring as you solve real-world business processes and learn about:

- Agile management

- Lean management

- Six Sigma Green Belt

- Lean Six Sigma Black Belt

- Quality management

- Digital transformation

Become a Lean Six Sigma Expert with the post graduate program delivered by Simplilearn in collaboration with the University of Massachusetts. Download the program brochure to learn more about the Lean Six Sigma course. This program is accredited by the International Association for Six Sigma Certification (IASSC) and has professors who can share real-world experiences to help bring these complicated concepts to life.

You might also like to read:

The Top 24 Lean Six Sigma Interview Questions for 2023

Six Sigma Methodologies for Process Improvement

Ultimate Guide to Six Sigma Control Charts

Process Mapping in Six Sigma: Here’s All You Need to Know

What Are the Elements of a Six Sigma Project Charter?

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

Recommended Articles

What Is Lean Management? Principles & Everything You Need to Know

Discover the essence of lean management – a powerful approach to streamline processes and maximize efficiency. Explore its principles and benefits in our comprehensive guide.

What is Process Mapping in Six Sigma? Here’s Everything You Need to Know

Demystifying Process Mapping in Six Sigma: Learn to optimize workflows and enhance quality. Dive into this essential quality management tool.

Six Sigma Black Belt Salaries in 2024: Everything You Need to Know!

Get to know about salaries and factors affecting six sigma black belt salary and the skills required to have an incremental effect on your pay scale.

A Guide to Failure Mode and Effects Analysis

Explore Failure Mode and Effects Analysis with our easy-to-understand guide. Learn what it is, why it’s useful, how to use it, and its key applications.

A Guide to Design of Experiments in Six Sigma

In today’s hypercompetitive world, organizations must streamline their operations and workflows to stay ahead of the game. Lean Six Sigma and the design of experiments are methodologies that can help them do this. Learn more in this article.

A Guide to Six Sigma Projects

Originally developed for manufacturing processes, the Six Sigma methodology is now leveraged by companies in nearly all industries. In this article, we will share information about successful Six Sigma projects, methods, and more.

Lean Six Sigma Certification

Learning Format

Online Bootcamp

Program benefits.

- Green and Black Belt exam training material included

- Aligned with IASSC-Lean Six Sigma

- Masterclasses from top faculty of UMass Amherst

- UMass Amherst Alumni Association membership

What Is Lean Six Sigma?

Lean Six Sigma combines lean manufacturing and Six Sigma to help organizations improve their processes and reduce waste. Here’s why it’s effective.

Lean Six Sigma brings together principles from lean manufacturing and Six Sigma. Lean manufacturing is a philosophy that emphasizes the elimination of waste and the improvement of production flow through collaborative team effort. Six Sigma is a data-driven methodology that uses statistical analysis and problem-solving tools to identify and eliminate defects as well as process variations. Lean Six Sigma combines these methodologies to increase organizational efficiency.

Why Is Lean Six Sigma Important?

The combination of lean and Six Sigma methodologies provides a comprehensive approach to process improvement that can help organizations streamline their operations, reduce costs and improve quality, thereby leading to significant improvements in efficiency and customer satisfaction.

More From This Expert What Is Software Quality Assurance?

Lean Six Sigma Techniques

Lean Six Sigma uses a variety of techniques to improve processes and reduce waste.

Value Stream Mapping

VSM is a tool we use to identify and eliminate waste in a process by mapping out the entire value stream, from the start of the process to the end.

DMAIC

DMAIC (Define, Measure, Analyze, Improve, Control) is a problem-solving methodology used to improve existing processes by identifying and eliminating the root cause of problems.

What Are the 5 Phases of Lean Six Sigma?

The Lean Six Sigma methodology typically consists of five phases known as DMAIC, which stands for define, measure, analyze, improve and control.

Kanban

Kanban is a visual management tool that helps manage and control the flow of work by using cards or other visual indicators to signal where tasks are within a given project workflow.

5S is a workplace organization methodology that aims to improve efficiency and productivity by creating a clean, safe and organized work environment.The term 5S stands for the five Japanese words that describe the steps involved in the method: seiri (sort), seiton (set in order), seiso (shine), seiketsu (standardize) and shitsuke (sustain).

Poka-Yoke

Poka-yoke is a mistake-proofing technique used to prevent errors from occurring in a process by designing products or processes that make it impossible for errors to occur. We can accomplish this by implementing physical or visual cues that alert the worker to a potential mistake or prevent the mistake from happening in the first place.

For instance, most modern microwave ovens have a safety mechanism that prevents the oven from operating if the door is not properly closed. This ensures that the user will not accidentally turn on the microwave with the door open, which could result in injury. This is a perfect example of Poka-Yoke implementation that protects users from injuries.

Statistical Process Control (SPC)

SPC is a technique used to monitor and control a process by using statistical methods to measure and analyze data . Control charts, process capability analysis and sampling plans are among these statistical methods used in SPC.

Sampling plans help us determine how many samples of a product or process output we should take for analysis. The goal is to obtain enough data to make accurate inferences about the overall process performance while minimizing the cost and time required for data collection and analysis.

Control charts help identify when a process is producing results that are outside of the expected range, which can signal the need for corrective action.

Process capability analysis involves calculating statistical metrics such as Cp and Cpk, which measure how well the process is centered and how much variation it produces.

Root Cause Analysis (RCA)

RCA is a problem-solving technique used to identify the underlying causes of problems by asking “why” until we reach the root cause.

Advantages of Lean Six Sigma

Improved quality.

- Increased Efficiency

Cost Reduction

Improved customer satisfaction, cultural change.

- Competitive Advantage

Lean Six Sigma methodologies are designed to improve process efficiency and reduce defects. By using data-driven analysis and process improvement techniques, Lean Six Sigma can help organizations improve product or service quality, which can lead to greater customer satisfaction and loyalty.

Increased Efficiency

Lean Six Sigma helps organizations identify and eliminate waste, non-value-added activities and other process inefficiencies. These improvements help reduce process cycle times, increase throughput and reduce costs, all of which lead to greater efficiency and productivity .

By reducing defects and inefficiencies, Lean Six Sigma can help organizations reduce costs associated with rework, scrap and other forms of waste. This can result in significant cost savings and improved profitability.

Lean Six Sigma helps organizations focus on customer needs and expectations, which can lead to improved customer satisfaction and loyalty. By reducing defects and improving quality, organizations can increase customer trust and confidence.

Lean Six Sigma methodologies emphasize collaboration, data-driven decision-making, customer value and a culture of continuous improvement .

The methodology encourages employees to constantly look for ways to improve processes, reduce waste and increase efficiency by promoting collaboration across teams. By breaking down silos and encouraging teamwork, it fosters a more positive and collaborative work environment.

Lean Six Sigma promotes data-driven decision making as it helps to establish a culture of continuous improvement. By regularly collecting and analyzing data on process performance, companies can identify trends and patterns that indicate areas for improvement.

Competitive Advantage

By improving quality, efficiency and customer satisfaction, Lean Six Sigma can help organizations gain a competitive advantage in the marketplace. This can lead to increased market share, revenue growth and improved profitability.

Lean Six Sigma Phases

1. define .

In this phase, we establish a project team. The team then works to define the project goals and objectives as well as identify the process to be improved. The team also clarifies the problem and the customer’s requirements.

2. Measure

In this phase, teams measure and baseline the current performance of the process, collect data and develop a process map (or flowchart) to understand the process steps and potential areas for improvement.

3. Analyze

In this phase, teams analyze data to identify the root cause of problems and process variations. The team may use statistical analysis and other tools to help them identify the most significant causes of process problems.

4. Improve

In this phase, the team develops and implements process improvements by using the information gathered in the previous phases. The team may use lean tools to reduce waste, improve flow and make the process more efficient. The team may also use Six Sigma tools to reduce variation and improve quality.

5. Control

Finally, the team monitors and sustains process improvements over time. During the control phase, teams focus on monitoring and sustaining the improvements achieved in the previous phase. The team also develops a control plan to monitor the process and take corrective action when necessary.

More From Built In Experts Is Your Strategy Still Working?

DMAIC in Lean Six Sigma vs. Six Sigma

The DMAIC process in Six Sigma and Lean Six Sigma is essentially the same. However, there are some key differences in how we apply DMAIC in the context of Six Sigma versus Lean Six Sigma.

In Six Sigma, DMAIC is typically focused on improving the quality of a process by reducing defects and minimizing variability. The emphasis is on achieving statistical process control and improving process capability. The team may use statistical tools such as hypothesis testing, design of experiments and control charts to identify and eliminate sources of variation and improve process performance.

In Lean Six Sigma, we use the DMAIC process to improve both the quality and efficiency of a process by reducing waste and improving flow. The team may use lean tools such as value stream mapping, 5S and kaizen events to identify and eliminate non-value-added activities and streamline the process flow. The team may also use Six Sigma tools to reduce variability and defects and improve quality.

Another key difference is that Lean Six Sigma places a greater emphasis on the customer and their needs throughout the DMAIC process. Teams identify and analyze customer needs in the define phase, then monitor and measure customer satisfaction throughout the process. This helps ensure the process improvements are aligned with the needs of the customer and deliver value to the organization.

Expert Advice for Entrepreneurs and Leaders How to Create Great Documentation for Your Business Processes

Lean Six Sigma Belt Levels

Lean Six Sigma uses a belt system to denote different levels of expertise and responsibilities within the organization. The belt system is based on the martial arts belt system, where darker belts indicate a greater level of expertise. Each belt level has its own set of responsibilities and requirements for certification.

There are five levels of Lean Six Sigma belts.

White Belt

This is the introductory level of Lean Six Sigma training and provides an overview of the basic concepts and principles of Lean Six Sigma.

Yellow Belt

Yellow belt training provides a more detailed understanding of the Lean Six Sigma methodology and prepares individuals to participate in improvement projects.

Green Belt

Green belt training provides a comprehensive understanding of Lean Six Sigma tools and techniques and prepares individuals to lead improvement projects.

Black Belt

Black belt training provides advanced training in Lean Six Sigma tools and techniques and prepares individuals to lead complex improvement projects and manage improvement programs .

Master Black Belt

Master black belt training provides the highest level of training in Lean Six Sigma and prepares individuals to be experts in the methodology and lead strategic improvement initiatives while mentoring and training others.

In addition to these belt levels, there are also Lean Six Sigma Champions who provide executive sponsorship and leadership for improvement initiatives, as well as Lean Six Sigma Facilitators who provide training and support for improvement projects.

Lean Six Sigma vs. Six Sigma

Lean Six Sigma and Six Sigma are two related methodologies that share the goal of improving business processes and reducing defects. However, there are some key differences between the two.

Six Sigma is a methodology that focuses on reducing defects and improving quality by using statistical analysis to measure and improve process performance.

Lean Six Sigma, on the other hand, combines the principles of lean manufacturing and Six Sigma. In addition to the DMAIC process, Lean Six Sigma also includes lean manufacturing principles such as value stream mapping, 5S and Kanban to improve process efficiency.

The main difference between Lean Six Sigma and Six Sigma is that Lean Six Sigma places a greater emphasis on the reduction of waste and non-value-added activities, while Six Sigma focuses more on reducing defects and improving process quality.

Another difference is that Lean Six Sigma is more focused on continuous improvement and cultural change, while Six Sigma is more focused on solving specific problems and implementing process improvements.

Recent Expert Contributors Articles

- Consultancy

- Online Courses

SIGN UP TODAY

- Lean , Lean Wiki , Six Sigma

DMAIC Model | The 5 Phase DMAIC Process to Problem-Solving

- 5 mins to read

- July 1, 2020

- By Reagan Pannell

Summary: An Introduction to DMAIC

Dmaic – the dmaic model.

The 6 Sigma DMAIC model remains the core roadmap for almost all Lean Six Sigma problem-solving approaches that drive quality improvement projects. It is used to ensure a robust problem-solving process is followed to give the best chance of the best solution being found.

A note about the structure and the approach used in this article.

Our approach to DMAIC follows Quentin Brook’s book “Lean Six Sigma & Minitab” which for anyone wishing to study Lean Six Sigma is a must for the Green Belt Course and the Black Belt Course .

What is the dmaic model.

DMAIC is short for: Define, Measure, Analyse, Improve and Control. These are the key phases that each project must go through to find the right solution. This flow is the concept behind DMAIC Analysis of an issue and its the DMAIC cycle all projects must go through.

As you can quickly see from the 5 DMAIC phases they follow a logical sequence as we will go through in more detail below. But they also make sure you do not try to jump to implementing a solution before you have properly, defined and measured what you are going to be an improvement.

We all love to jump to solutions, but the DMAIC problem-solving structure helps us have a more rigorous approach so that we do not short cut the process and perhaps miss the best solution or perhaps implement the wrong solution as well. It can help companies better structure their problem-solving approaches and be more robust in their approach.

DMAIC – The 5 DMAIC Process Phases

The phases throughout the DMAIC model have and can be broken down in many different ways. One of the best approaches we have found is from Opex Resources which shows how to examine the existing processes, and with a project team, and the sigma improvement process, we can solve complex issues.

DMAIC Define Phase

The purpose of the Define phase is ultimately to describe the problems that need to be solved and for the key business decision-makers to be aligned on the goal of the project. Its about creating and agreeing the project charter .

All too often, teams have identified solutions without actually defining what it is they will actually be trying to do or perhaps not do. This can lead to internal confusion and often solutions which completely miss the business requirements and needs.

- Define the Business Case

- Understand the Consumer

- Define The Process

- Manage the Project

- Gain Project Approval

DMAIC Measure Phase

In the measure phase, the goal is to collect the relevant information to baseline the current performance of the product or the process. In this stage, we want to identify the level of “defects” or the errors that go wrong and use the baseline to measure our progress throughout the project.

The key goal of this phase is to have a very strong and clear measure/baseline of how things are performing today so that we can always monitor our progress towards our goals. We need to understand our cycle times , process times, quality metrics.

Many projects are delivered without clear benefits being shown because the team never fully baseline the current status before making changes.

The Measure phase can be broken down into 5 key areas:

- Develop Process Measures

- Collect Process Data

- Check the Data Quality

- Understand Process Behaviour

- Baseline Process Capability and Potential

100% Free Fundamentals of Lean COURSE

Take our free course.

JOIN FOR FREE

Join our Lean Six Sigma Yellow Belt Certification Course

We can’t solve problems by using the same kind of thinking we used when we created them” Albert Einstein Tweet

DMAIC Analyse Phase

The goal of the DMAIC Analyse phase with the lean six sigma improvement process is to identify which process inputs or parameters have the most critical effect on the outputs. In other words, we want to identify the root cause(s) so that we know what critical elements we need to fix.

During this phase, the teams need to explore all potential root causes using both analytical approaches, statistical approaches or even graphical tools such as VSM’s and Process maps to uncover the most important elements which need to be changed/fixed.

The Analyse phase can be broken down into:

- Analyse the Process

- Develop Theories and Ideas

- Analyse the Data

- and finally, Verify Root Causes

DMAIC Improve Phase

The goal of the improvement phase is to identify a wide range of potential solutions before identifying the critical solutions which will give us the maximum return for our investment and directly fix the root cause we identified.

During this phase, the team brainstorm, pilot, test and validate potential improvement ideas before finally implementing the right solutions. With each pilot, the team can validate how well it improves the key measures they identified back in Define and Measure. When the team finally roll out the solution, the results should be seen if the right solution has been found and implemented correctly.

The Improve phase can be broken down into:

- Generate Potential Solutions

- Select the Best Solution

- Assess the Risks

- Pilot and Implement

DMAIC Control Phase

The final part of the DMAIC Model is the Control phase where we need to ensure that the new changes become business as normal and we do not revert to the same way of working as before.

During this phase, we want to ensure that we close the project off by validating the project savings and ensuring the new process is correctly documented. We also need to make sure that new measures and process KPI’s are in place and, finally that we get the business champion to sign off on both the project and the savings. We may need to redesign the workplace following the 5S principles .

The Control phase can be broken down into:

- Implement Ongoing Measurements

- Standardise Solutions

- Quantify the Improvement

- Close The Project

The key closing documents of the Control Phase is a Control Plan that documents all the changes and process steps with key risks, standard work instructions and the Project Close-Out document signed by the business owners to accept the change and the validated benefits.

The DMAIC Model vs. A3 Management vs. 8D Problem Solving

The DMAIC model is not the only project management roadmap. Two others which are important is the A3 format which originally comes from Toyota and is very Lean focused and the 8D which draws more of the DMAIC structure but with the 1-page idea of the A3.

Everyone has their own preference but each method is interchangeable. The DMAIC Structure lends its self naturally to a multi-slide Powerpoint presentation. Whereas the A3 is a single-page document which is perfect for internal communication and adding into War Rooms and Control Towers.

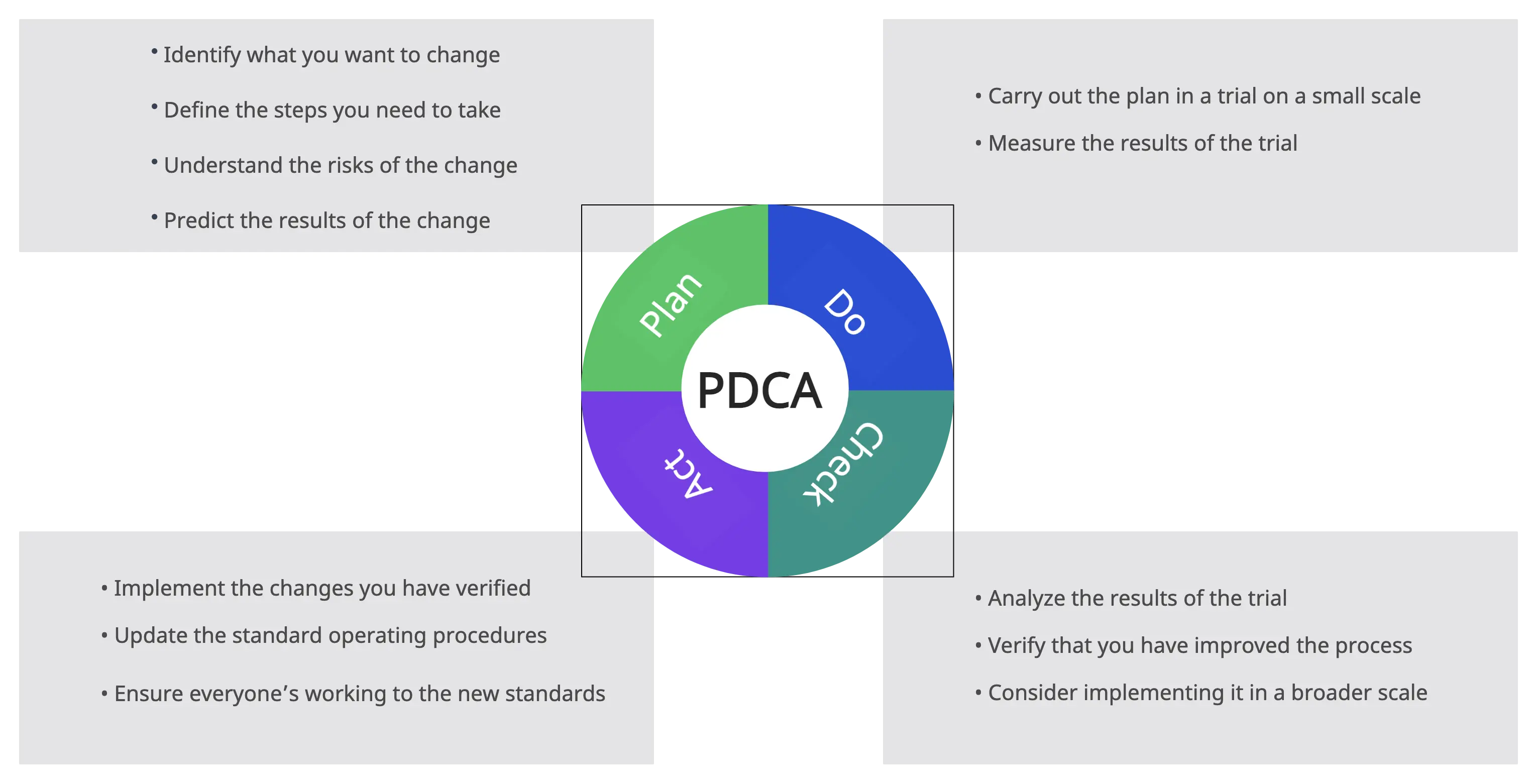

What’s important is that every problem-solving approach follows the PDCA (Plan, Do, Check and Act) Scientific Problem Solving format. The reset is just a preference or using the right tool in the right circumstances.

- Corporate Training

- Courses for Individuals

Our Newsletter

Reagan pannell.

Reagan Pannell is a highly accomplished professional with 15 years of experience in building lean management programs for corporate companies. With his expertise in strategy execution, he has established himself as a trusted advisor for numerous organisations seeking to improve their operational efficiency.

Our Training Courses

Fundamentals of lean.

- Lean Six Sigma White Belt Course

- Lean Thinking Business Course

- Lean Six Sigma Yellow Belt Course

- Lean Six Sigma Green Belt Course

- Lean Six Sigma Black Belt Course

Yellow Belt Course

View all courses, recent articles, 5 essential problem-solving strategies every business leader should know, unveiling the secrets of blue ocean strategy for business growth, the difference between strategy and strategic execution, small steps, big gains: the case for incremental improvement, maximising efficiency and profitability: exploring the benefits of lean consultancy, empowering leaders: the imperative for problem-solving training, view all articles, green belt course, other articles, how to improve your decision making | learn what is noise, how to get lean six sigma green belt certified, the benefits of continuous improvement, what qualities do employers look for in potential employees, get your company to fund your lean six sigma training, what is the % defective in lean six sigma, what is jidoka what does jidoka mean | leanscape, sources of measurement error – bias and precision, kaizen vs kaikaku – understanding the difference, 6 sigma control charts – statistical process control charts, why the fmea is a great tool for all project managers, related articles, agile project management: a comprehensive guide, how to use lean six sigma programs to build cash flows, pareto’s principle: the 80/20 rule, online business courses free: the benefits for professionals, harnessing the wisdom of lee kuan yew for personal and professional growth, lean six sigma online courses.

FREE COURSE | YELLOW BELT | GREEN BELT | BLACK BELT | MASTERCLASS | WORKSHOPS

Lean Accelerator Progam

A Lean Six Sigma Green Belt Masterclass

Ready to start your journey into the world of Lean with this free course?

FREE COURSE

Lean Thinking

A Lean focused continious improvement certification course

LSS Yellow Belt

Propel your career forward, tackle complex problems and drive change

LSS Green Belt

The ultimate fast-track for future leadership

LSS Black Belt

Become an expert in change management and complex problem-solving.

Subscribe to Newsletter

Keep up to date to the latest insights, courses, training, webinars and more. Join our newsletter today.

Lean Accelerator Program

Discover the power of problem-solving, 15 min per day | 3-months | only €999 | learn from experts.

The Easy Guide to Solving Problems with Six Sigma DMAIC Method

The most commonly used methodology in Six Sigma is the DMAIC process. Many use it to solve problems and identify and fix errors in business and manufacturing processes.

In this post, we will look at how to use the DMAIC process to solve problems. You will also find useful and editable templates that you can use right away when implementing DMAIC problem-solving in your organization.

- What are 5 the Steps of Six Sigma

DMAIC Process and Problem-Solving

Common mistakes to avoid when using six sigma dmaic methodology, how to use the dmaic methodology for problem solving in project management, what are the 5 steps of six sigma.

DMAIC is one of the core methodologies used within the Six Sigma framework. It is a data-driven method used to systematically improve the process. The approach aims to increase the quality of a product or service by focusing on optimizing the process that produces the output. This way DMAIC seeks to provide permanent solutions when it comes to process improvement.

It provides a structured problem-solving framework to identify, analyze, and improve existing processes. DMAIC guides practitioners through a series of steps to identify the root causes of process issues, implement solutions, and sustain the improvements over time.

Following we have listed down the 5 phases of the DMAIC process along with the steps you need to take when using it to solve problems. Different tools for each phase is provided with editable templates.

Step 1: Define the Problem

So there’s a problem that affects your customer or your company processes. In this first step of the DMAIC problem solving method , you need to focus on what the problem is and how it has affected you as a company.

There are a few steps you need to follow in this phase.

• Create a problem statement which should include a definition of the problem in quantifiable terms and the severity of the problem.

• Make sure necessary resources such as a team leader and competent team members, and funds etc. are available at hand.

• Develop a goal statement based on your problem statement. It should be a measurable and time-bound target to achieve.

• Create a SIPOC diagram which will provide the team with a high-level overview of the process (along with its inputs, outputs, suppliers, and customers) that is being analyzed. You can also use a value stream map to do the same job.

• Try to understand the process in more in-depth detail by creating a process map that outlines all process steps. Involve the process owners when identifying the process steps and developing the map. You can add swimlanes to represent different departments and actors responsible.

Step 2: Measure the Problem

In this step, you should measure the extent of the problem. To do so you need to examine the process in its current state to see how it performs. The detailed process map you created in the ‘Define’ phase can help you with this.

The baseline measurements you will need to look into in this phase, are process duration, the number of defects, costs and other relevant metrics.

These baseline measurements will be used as the standards against which the team will measure their success in the ‘Improve’ phase.

Step 3: Analyze the Problem

The analyze phase of the DMAIC process is about identifying the root cause that is causing the problem.

• Referring to the process maps and value stream maps you have created, further, analyze the process to identify the problem areas.

• Visualize the data you have collected (both in the ‘Measure’ phase and the analyze phase) to identify signs of problems in the processes.

• Use Pareto charts, histograms, run charts etc. to represent numerical data. Study them with team leaders and process owners to identify patterns.

• With the results of your process analysis and your data analysis, start brainstorming the root causes of the problem. Use a cause and effect diagram/ fishbone diagram to capture the knowledge of the process participants during the session.

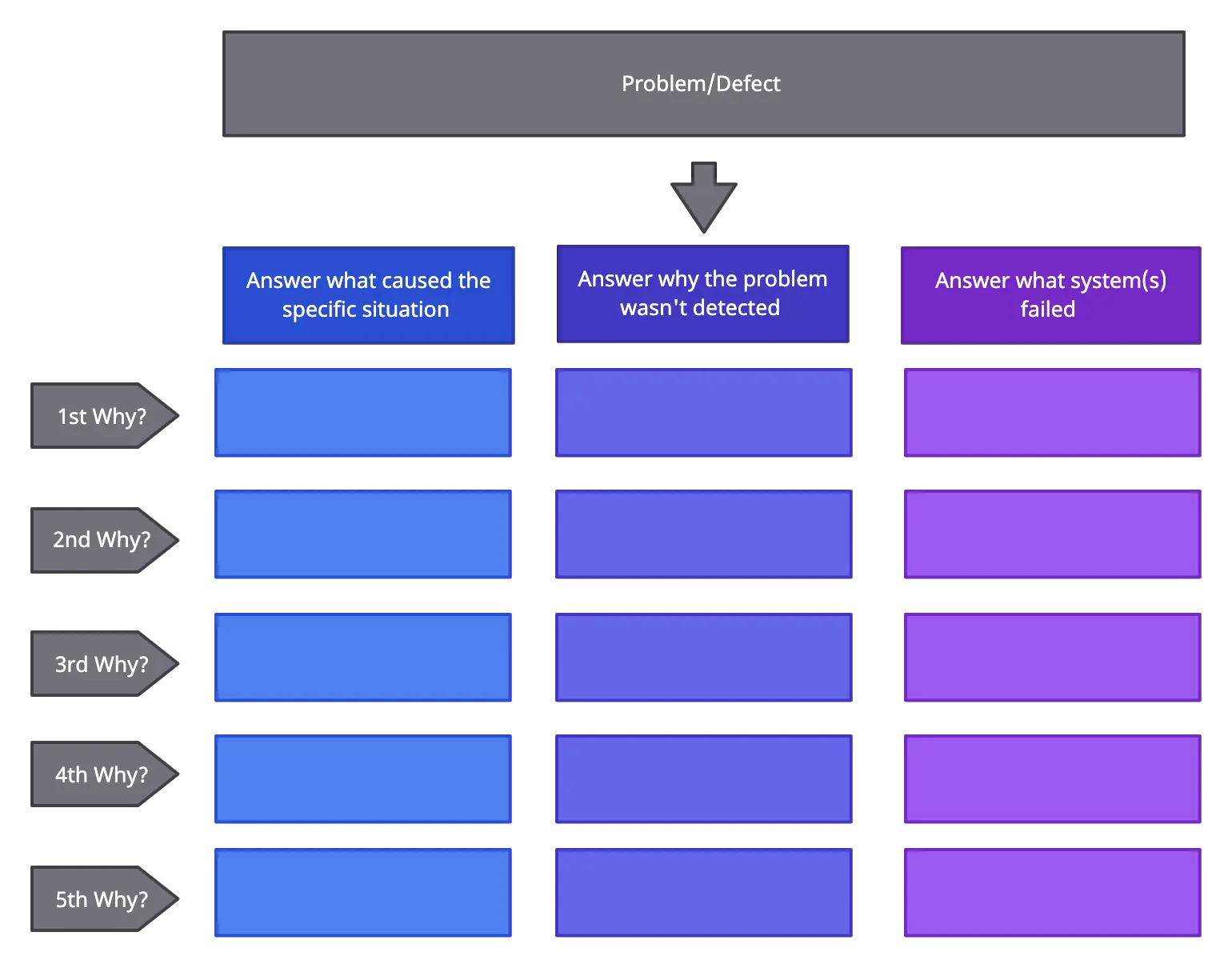

• Using a 5 whys diagram, narrow down your findings to the last few causes of the problem in your process.

Step 4: Improve (Solve the Problem)

In this phase, the focus is on mitigating the root cause identified and brainstorming and implementing solutions. The team will also collect data to measure their improvement against the data collected during the ‘Measure’ phase.

• You may generate several effective solutions to the root cause, but implementing them all would not be practical. Therefore, you will have to select the most practical solutions.

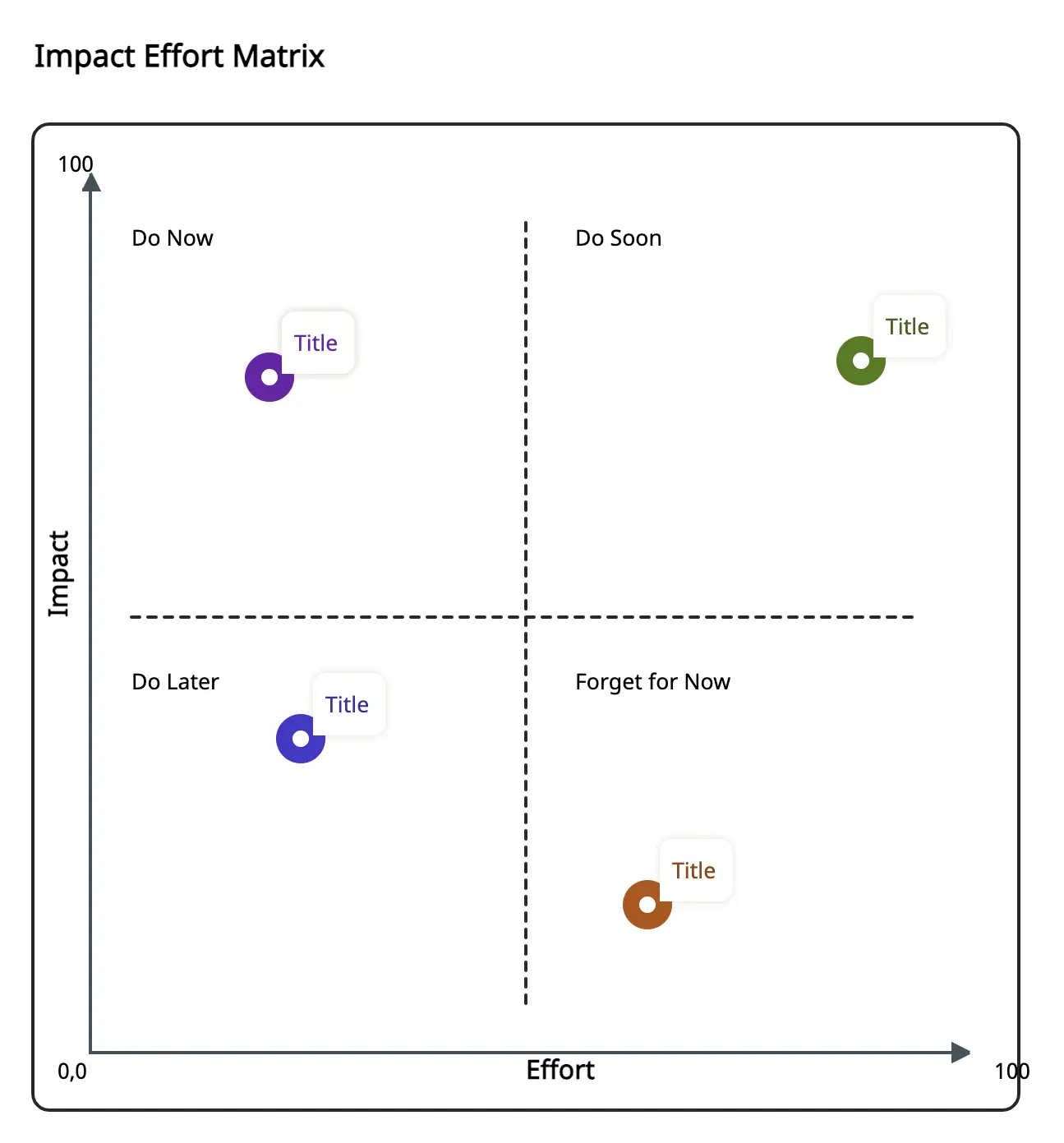

To do this you can use an impact effort matrix . It will help you determine which solution has the best impact and the least effort/ cost.

• Based on different solutions, you should develop new maps that will reflect the status of the process once the solution has been applied. This map is known as the to-be map or the future-state map. It will provide guidance for the team as they implement changes.

• Explore the different solutions using the PDCA cycle and select the best one to implement. The cycle allows you to systematically study the possible solutions, evaluate the results and select the ones that have a higher chance of success.

Step 5: Control (Sustain the Improvements)

In the final phase of the DMAIC method , the focus falls on maintaining the improvements you have gained by implementing the solutions. Here you should continue to measure the success and create a plan to monitor the improvements (a Monitoring plan).

You should also create a Response plan which includes steps to take if there’s a drop in the process performance. With new process maps and other documentation, you should then proceed to document the improved processes.

Hand these documents along with the Monitoring plan and the response plan to the process owners for their reference.

Insufficiently defining the problem can lead to a lack of clarity regarding the problem statement, objectives, and scope. Take the time to clearly define the problem, understand the desired outcomes, and align stakeholders' expectations.

Failing to engage key stakeholders throughout the DMAIC process can result in limited buy-in and resistance to change. Ensure that stakeholders are involved from the beginning, seeking their input, addressing concerns, and keeping them informed about progress and outcomes.

Collecting insufficient or inaccurate data can lead to flawed analysis and incorrect conclusions. Take the time to gather relevant data using appropriate measurement systems, ensure data accuracy and reliability, and apply appropriate statistical analysis techniques to derive meaningful insights.

Getting caught up in analysis paralysis without taking action is a common pitfall. While analysis is crucial, it’s equally important to translate insights into concrete improvement actions. Strive for a balance between analysis and implementation to drive real change.

Failing to test potential solutions before implementation can lead to unintended consequences. Utilize methods such as pilot studies, simulation, or small-scale experiments to validate and refine proposed solutions before full-scale implementation.

Successful process improvement is not just about making initial changes ; it’s about sustaining those improvements over the long term. Develop robust control plans, standard operating procedures, and monitoring mechanisms to ensure the gains achieved are maintained and deviations are identified and corrected.

Applying DMAIC in a one-size-fits-all manner without considering the organization’s unique culture, context, and capabilities can hinder success. Tailor the approach to fit the specific needs, capabilities, and culture of the organization to enhance acceptance and implementation.

In the project management context, the Define phase involves clearly defining the project objectives, scope, deliverables, and success criteria. It entails identifying project stakeholders, understanding their expectations, and establishing a project charter or a similar document that outlines the project’s purpose and key parameters.

The Measure phase focuses on collecting data and metrics to assess the project’s progress, performance, and adherence to schedule and budget. Key project metrics such as schedule variance, cost variance, and resource utilization are tracked and analyzed. This phase provides insights into the project’s current state and helps identify areas that require improvement.

The Analyze phase involves analyzing the project data and identifying root causes of any performance gaps or issues. It aims to understand why certain project aspects are not meeting expectations. Techniques such as root cause analysis, Pareto charts, or fishbone diagrams can be used to identify factors impacting project performance.

In the Improve phase, potential solutions and actions are developed and implemented to address the identified issues. This may involve making adjustments to the project plan, reallocating resources, refining processes, or implementing corrective measures. The goal is to optimize project performance and achieve desired outcomes.

The Control phase focuses on monitoring and controlling project activities to sustain the improvements made. It involves implementing project control mechanisms, establishing performance metrics, and conducting regular reviews to ensure that the project remains on track. Control measures help prevent deviations from the plan and enable timely corrective actions.

What are Your Thoughts on DMAIC Problem Solving Method?

Here we have covered the 5 phases of Six Sigma DMAIC and the tools that you can use in each stage. You can use them to identify problem areas in your organizational processes, generate practical solutions and implement them effectively.

Have you used DMAIC process to improve processes and solve problems in your organization? Share your experience with the tool with us in the comment section below.

Also, check our post on Process Improvement Methodologies to learn about more Six Sigma and Lean tools to streamline your processes.

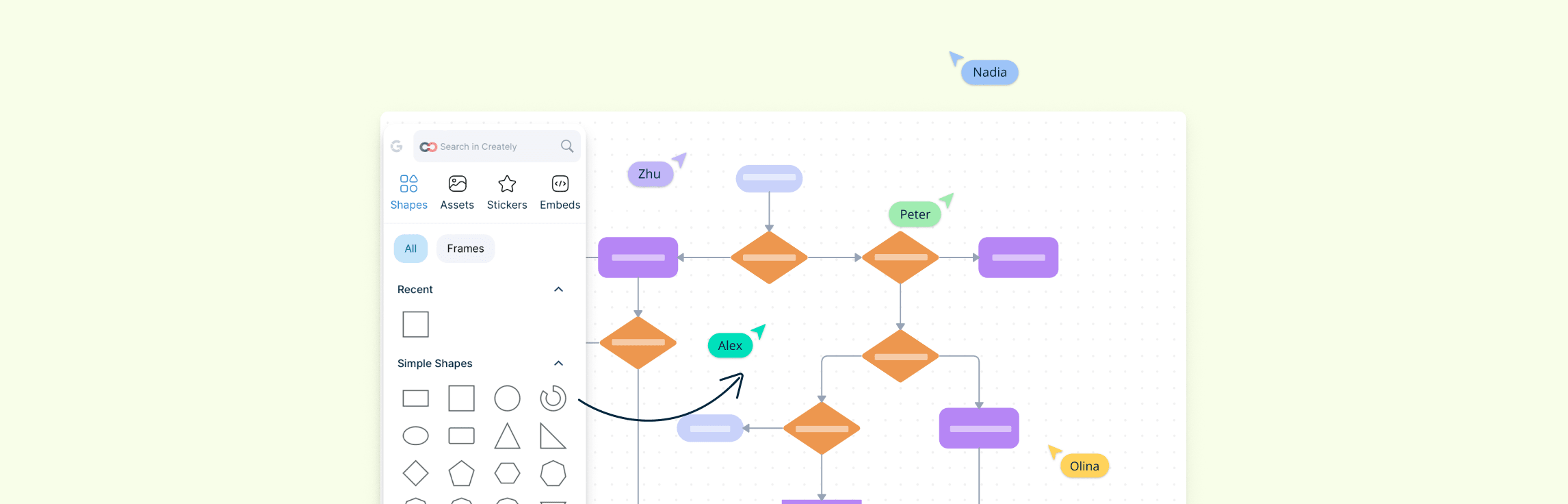

Join over thousands of organizations that use Creately to brainstorm, plan, analyze, and execute their projects successfully.

FAQs about Six Sigma and DMAIC Approaches

DMAIC and DMADV are two methodologies used in Six Sigma. DMAIC is employed to enhance existing processes by addressing issues and improving efficiency, while DMADV is utilized for creating new processes or products that meet specific customer needs by following a structured design and verification process.

- Used for improving existing processes

- Define, Measure, Analyze, Improve, Control

- Identifies problem areas and implements solutions

- Focuses on reducing process variation and enhancing efficiency

- Used for developing new products, services, or processes

- Define, Measure, Analyze, Design, Verify

- Emphasizes meeting customer requirements and creating innovative solutions

- Involves detailed design and verification through testing

Problem identification : When a process is not meeting desired outcomes or experiencing defects, DMAIC can be used to identify and address the root causes of the problem.

Process optimization : DMAIC provides a systematic approach to analyze and make improvements to processes by reducing waste, improving cycle time, or enhancing overall efficiency.

Continuous improvement : DMAIC is often used as part of ongoing quality management efforts. It helps organizations maintain a culture of continuous improvement by systematically identifying and addressing process issues, reducing variation, and striving for better performance.

Data-driven decision making : DMAIC relies on data collection, measurement, and analysis. It is suitable when there is sufficient data available to evaluate process performance and identify areas for improvement.

Quality control and defect reduction : DMAIC is particularly useful when the primary objective is to reduce defects, minimize errors, and enhance product or service quality. By analyzing the root causes of defects, improvements can be made to prevent their occurrence.

More Related Articles

Amanda Athuraliya is the communication specialist/content writer at Creately, online diagramming and collaboration tool. She is an avid reader, a budding writer and a passionate researcher who loves to write about all kinds of topics.

- Guide: DMAIC

Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

- Last Updated: June 2, 2023

- Learn Lean Sigma

The DMAIC methodology is a popular problem-solving framework that is used to drive process improvements and achieve measurable results. Businesses can improve efficiency, quality, and customer satisfaction by using a structured and data-driven approach to identify, analyze, and address issues.

Table of Contents

The dmaic steps, step 1: define.

In step one of the DMAIC process, you are focused on defining, which involves defining all of the elements of the improvement process and is one of the most important stages as it lays the foundation for stages that follow and ensures the project goes on the right track.

By the end of the define stage, the project should have the following defined:

- Define the problem

- Defined goal

- Defined the process

- Identify the customers and their needs ( VOC )

- Identify Stakeholders

- Define the project timeline

DMAIC Project Report Template- Page 1

Step 2: Measure

After successfully defining the problem you are looking to resolve or the process you want to improve, it is time to work on the measurement phase, which involves collecting data on the problem to verify what the problem is.

Within this you will work with a cross-functional team to initially create a data collection plan which will plan out what data is needed to verify the problem and also help with the analysis stage that comes next.

The data collection plan plans out what data will be collected, where it is collected from when it will be collected, the frequency, who will record it and the method. To get an in-depth understanding, take a look at the Data Collection Guide.

Once you have this data collected, you should be able to get a baseline measurement understanding of the process, which would be referred to as the current state.

Another way the measure phase can be conducted is by creating a process map to define the process “as-is,” or the current state of how the process is being completed.

Detailed sub process map

By mapping out the process, you can analyse the current state and later create the future state process map that will look to improve the process and remove waste from the process in relation the 8 Process Wastes

Value add analysis example

Step 3: Analyze

Following the collection of the data needed to understand the problem, the next step is to conduct analysis, which in Lean Six Sigma is a huge topic as there are many ways analysis can be done depending on the problem and the type of data that you have.

In the analysis phase, some of the methods that can be used include Fishbone Diagram, 5 Whys and FMEA for non-numerical data. However, for numerical data, the list of tools includes the following:

- Hypothesis Testing

- Correlation Analysis

- Regression Analysis

- Pareto Chart

- Scatter Plot

- Time Series Plot

We could not cover all of these methods within this guide. However, if you are looking to use one or more of these methods, consult our guides section to learn more about them and how to conduct the analysis.

This analysis is done to verify the root causes of problems, understand what is causing them, and direct the improvement team to know what action needs to be taken to address them.

DMAIC-Template-Example-Page-2

Step 4: Improve

After the analysis has been completed, and the root cause of the problem has been identified, the project team should conduct a brainstorming session to gather various potential solutions to the problem.

Once the brainstorming has been done and the solutions have been identified, the team should then create a plan for implementation. This will likely be in the form of an action plan that sets out what the actions are when they need to be done, and who will do them.

The plan will likely involve pilot testing the improvements by conducting small tests or trials and analyzing the results before full implementation. It is also common practice to conduct a cost-benefit analysis to evaluate if it is feasible to take full advantage of the potential solutions.

Step 5: Control

Once the improvements are in place, they need to be controlled and sustained to ensure that they are long-term solutions and not short-term ones, following the improvement and then reverting back to pre-improvement levels.

This is usually done using tools such as control charts that collect data at regular intervals to measure process performance, supported by updating documentation and standard operating procedures that confirm and formalize any changes to the process. It could also include updating any training to individuals involved with the process and regular audits of the process.

DMAIC-Template-Example-Page-3

DMAIC Template

If you are looking to use the DMAIC methodology you might find it useful to use the DMAIC project report template to structure and communicate your project to the business. Feel free to download it from the template section.

The DMAIC methodology is a proven, structured approach for process improvement that stands for Define, Measure, Analyze, Improve, and Control. As a backbone of Lean Six Sigma, it offers a comprehensive roadmap for problem-solving and optimizing business processes.

Starting with the ‘Define’ phase, the methodology emphasizes laying a strong foundation by setting objectives and assembling a team. The ‘Measure’ phase focuses on collecting relevant data to understand the current state. Then comes ‘Analyze,’ where the focus shifts to identifying root causes through a variety of analytical tools. ‘Improve’ involves brainstorming solutions and pilot testing, while the ‘Control’ phase ensures that improvements are sustainable over the long term. Altogether, DMAIC offers a complete, data-driven strategy for achieving measurable improvements in efficiency, quality, and customer satisfaction.

- Berardinelli, C.F., 2012. TO DMAIC or not to DMAIC? . Quality Progress , 45 (11), p.72.

- De Mast, J. and Lokkerbol, J., 2012. An analysis of the Six Sigma DMAIC method from the perspective of problem solving. International Journal of Production Economics , 139 (2), pp.604-614.

A: DMAIC stands for Define, Measure, Analyze, Improve, and Control. It is a structured problem-solving methodology used in Six Sigma to improve processes and reduce defects.

A: The purpose of DMAIC is to identify and address problems or inefficiencies in a process, leading to measurable and sustainable improvements. It provides a framework for problem-solving and continuous improvement.

A: The steps in DMAIC are as follows:

- Define: Clearly define the problem and project goals.

- Measure: Gather data and measure the current state of the process.

- Analyze: Analyze the data to identify the root causes of the problem.

- Improve: Develop and implement solutions to address the identified causes.

- Control: Establish control mechanisms to sustain the improvements made and prevent future issues.

A: No, DMAIC is a versatile problem-solving methodology that can be applied to various industries and processes, including manufacturing, service, healthcare, software development, and more. It is applicable wherever there is a need for process improvement and reducing defects.

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Download Template

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Other Guides

How to Solve Your Problems With Lean Six Sigma (Free DMAIC Checklist)

Elisabeth Swan is the co-author of “The Problem-Solver’s Toolkit” and co-host of “The Just-in-Time Cafe Podcast.” She’s been a process improvement consultant, speaker, and innovator for over 30 years. She’s the Chief Learning Experience Officer for GoLeanSixSigma.com, a former cast member of ImprovBoston, and – if asked – may still be able to ride a unicycle.

Surgeon Atul Gawande made headlines when he told the world that a simple checklist could drastically reduce unnecessary deaths in The Checklist Manifesto .

Yet, checklists conjure images of forklift drivers on loading docks with clipboards counting boxes. How could they transform healthcare?

“ He has… produced a 90-second checklist which reduced deaths and complications by more than one-third in eight hospitals around the world – at virtually no cost and for almost any operation. ” – James Clarke, reviewing The Checklist Manifesto, Ulster Med J. 2011 Jan; 80(1): 54.

Aviation was transformed decades earlier when management and engineers at Boeing Corporation created the pre-flight checklist after the 1935 crash of the prototype Boeing B-17 at Wright Field in Dayton, Ohio. Checklists have become so essential to the airline industry that most crashes can be traced to the misuse or failure to complete a checklist.

A New York Times reviewer noted, “no matter how expert you may be, well-designed checklists can improve outcomes”. Since the purpose of process improvement is improving outcomes, Lean Six Sigma and checklists are natural companions.

To prove that, this Process Street blog post will show the relationship between checklists and lean six sigma, and provide you with a free DMAIC Improvement Project Tollgate Checklist that you can use right now.

Use the links below to jump to that section of the post:

Lean Six Sigma and the role of problem-solving

Lean six sigma & the checklist, introduction phase, define phase, measure phase, analyze phase, improve phase, control phase, checklists and lean six sigma, use process street to reduce error.

Or, if you just want the checklist, check it out below!

Let’s get started.

For those unfamiliar with Lean Six Sigma and process improvement, it is a structured approach for organizations to scrutinize how things are done, poke at data and processes to uncover waste and then cut out things like extra forms, out-dated approvals and other time-wasting steps.

It’s a customer-focused, 5-step problem-solving model that engages entire workforces to constantly seek a better way of doing things.

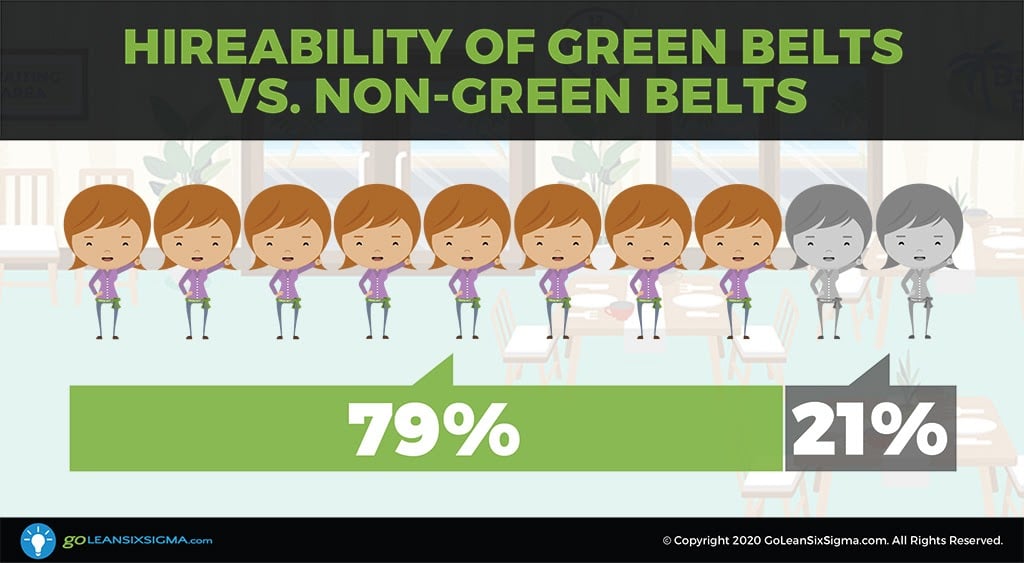

Proof of Lean Six Sigma’s influence is evident in today’s hiring practices. A poll by GoLeanSixSigma highlights that hiring managers prefer a person who is “ Green Belt Certified ” – having substantial Lean Six Sigma skills – by an almost 80% margin. In an interview with the former head of Twitter, problem-solving emerged as the top skill sought by today’s most influential hiring managers.

In other words, problem-solving (especially via Lean Six Sigma) is an absolutely vital skill.

If problem-solving is a must-have skill and checklists are key to good outcomes, then combining the two makes sense.

DMAIC – Define, Measure, Analyze, Improve & Control – is the 5-Step model for Lean Six Sigma and there’s a set of required tollgates at the end of each phase. These tollgates outline what has to be done in order to move the problem-solving process forward.

Using the tollgates as an outline, we created a dynamic Process Street template that you can use for free and run checklists from to track your progress!

Before you can start solving problems, you need a problem to solve.

Picking a process issue – and finding someone in leadership to support you – are two required tasks in this first tollgate. Scoping the project is important (bigger than a “just-do-it” and smaller than “solving world hunger”) but even more critical is finding a Sponsor.

Finding a Sponsor

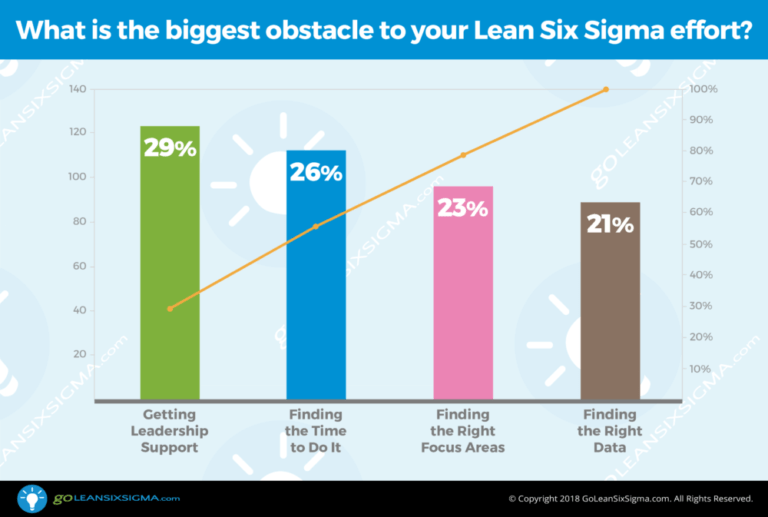

In a poll asking Lean Six Sigma practitioners what they considered the biggest obstacle to process improvement success, “Getting Leadership Support” accounted for almost a third.

When we coach team leads who tell us they can’t find someone to back their project, we let them know, “No Sponsor, no project”. If nobody in charge has any skin in the game, there’s no point in attempting the process fix. Find a different project that leadership supports.

One thing that helps when searching for leadership backing is being able to explain what Lean Six Sigma is and why it makes a difference. Since the checklist template is dynamic we inserted a video in the Define Phase within the checklist item, “Enlist a Project Champion/Sponsor who will support you and the project”. The team lead can share the video with managers or directors who they consider Sponsor candidates.

There’s also a Project Selection Guide Template embedded in the checklist so users can take a project idea and put it through a few screening questions. Is it a repeating problem? Is there a way to measure it? The checklist serves as a reminder, a source of templates, supporting videos and other just-in-time guidance.

The next set of tollgate tasks cover the Define Phase of DMAIC. This is where problem-solvers clarify the problem, the process impacted and customers of the process.

There is a journey of discovery during this phase as everyone agrees on the issue to solve. One of the big challenges is the tendency of ambitious team leads—or equally ambitious Sponsors—to try to “shoot the moon.”

Shooting the moon

They might want to reduce cycle time, reduce defects , improve margins, and increase customer satisfaction all by next Tuesday. But a project that focuses on everything accomplishes nothing. It’s okay to measure the cost reduction that results from reducing defects. But pick one of those to be the goal. Success is more possible if you focus on one goal at a time .

It takes practice and discipline to develop a manageable goal statement. Another moon shot is aiming for perfection out of the starting gate. When we see a goal statement that claims the team will, “reduce defects from 25% to 0%” then we know there is a sizable risk of failure and disappointment.

That’s why the Define Phase of the checklist includes a Goal Builder Template along with a blog providing tips on how to create well-crafted goal statements.

The primary focus of the Measure Phase is to baseline the process. If you’re trying to reduce defects, you need to know how you’re doing at that now. What’s your track record? You need to know the baseline of the process in order to measure whether or not you made a difference with your improvement when you get to the Improve Phase.

You need to know the gap, so you can close the gap.

The data’s in the system, somewhere…

One of the issues we run into in this phase is problem solvers assuming that data is sitting in a system somewhere waiting to be accessed. If they simply run a report, they’ll have the baseline. Check that off the list. But that rarely goes according to plan.

Maybe there’s system data, but was it entered with care? Is it reliable? We’ve seen teams struggle to use data that didn’t make sense. They could access cycle time data, but it didn’t take into account that the workday ended at 5:00. I had another team looking at why healthcare invoices had to be manually adjusted. They looked up the defect codes and the biggest category was “Other”. System data existed, but it was useless.

Most of the time, it helps to collect some data manually. In order to think through your approach, you need a Data Collection Plan. That involves listing the data you want and considering things like stratification factors—the “who, what, when, where” of data. If you’re looking at defects, should you collect data on defects by product? Defects by the fields on a form? Defects by customer type?

Within the task: “Develop a Data Collection Plan with Operational Definitions and create Check Sheets as Needed”, we’ve embedded a template (The Data Collection Plan) and a video to guide the process.

You’ll learn a lot by collecting the data firsthand, so if the perfect data set is not magically sitting in the system, it helps to have a plan.

Analyze is the crux of the DMAIC method. This is where learners drill down and discover the root cause of the process problem they’ve been chasing. Once you do that, you can solve the problem for good.

But if you have not determined the root cause then you might be solving a “symptom,” putting a bandaid on the problem or implementing a change based on a hunch. All of this means there’s a high likelihood the problem will remain and the efforts will have been in vain.

Finding the smoking gun

If you’ve always been told, “don’t bring me a problem, bring me a solution,” that’s an encouragement to jump right past this step into the fun of solutions. I’ve seen teams go with their assumptions regardless of what the data says or the process analysis reveals. I’ve seen Sponsors who tell teams what solutions they want to be implemented right from the get-go.

How do you stick with analysis long enough to find the smoking gun? The trick is to keep collecting the clues in the Cause & Effect Diagram , aka The “Fishbone Diagram”. It’s an aptly named tool, popularized by Dr. Ishikawa , which resembles a fish skeleton. Its construction allows teams to develop root cause theories around a problem as they build their knowledge of the process.

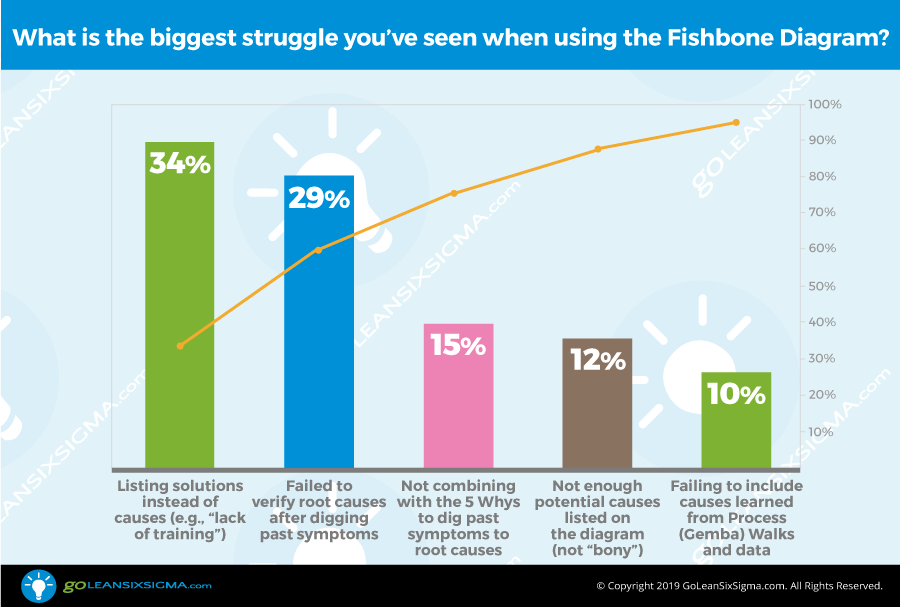

Each time they collect data, interview process participants on a Gemba Walk or map the process steps, they uncover potential reasons for defects. Making the most of the Fishbone Diagram is key but, during a poll, users reported where they fell short.

Solutions masquerading as problems

Over a third of respondents reported the issues of “listing solutions” on the Fishbone instead of causes. What we hear are phrases like, “the root cause is a lack of training”.

The problem with “lack of” anything is that it’s a sneaky way of putting a solution on the Fishbone.

The question is, “what is the training addressing?” Is it lack of user knowledge? If that’s the problem, could it be solved with helpful visuals, a simpler process? There are a lot of ways to address user knowledge before jumping to more employee training.

This is when you want to behave like the persistent detective – think Columbo, the classic 70’s TV icon. Every question helps you accumulate clues. People working through the process may have the answer without knowing it. The trick is to keep looking upstream until you find potential culprits. Dig past the symptoms.

To help with this phase, the checklist includes both a Fishbone Diagram Template as well as a video on how to get the most out of the Fishbone.

The Improve Phase is a long-anticipated step in the journey. It’s the step teams generally want to jump to from the start. Testing countermeasures, piloting solutions, watching the problem disappear, that’s the fun of process improvement. If you’ve done a proper job of Define, Measure, and Analyze, this phase falls nicely into place.

The ripple effect

The catch? Unintended consequences.

If you toss a stone into a lake you can see the ripples flow out from the center. The same principle holds true for process change. If you remove a step, change a form, skip an approval , will things fall apart? For that, we look to the Failure Modes & Effects Analysis or FMEA for short.

It’s a methodical way of assessing the potential for things to go wrong. It Involves deciding the potential severity and frequency of future problems and then mistake-proofing the process to prevent them. The technique originated at NASA since they couldn’t risk trial and error when sending men to the moon. By thinking through the risks of change they developed the kind of contingency plans you saw on display in movies like Apollo 13.

That’s why there’s an FMEA Template and a video on how to use it tucked into the main checklist from this post.

It’s okay to make changes. It’s simply key to think through the impact of those changes on other parts of the business.

Process Improvement can happen quickly and have a dramatic impact, but it’s critical to “stick the landing.” The Control Phase exists to see the improvement through to stability.

If teams move on and everyone takes their eyes off the ball, things may start to slip. What they need is the ability to continuously see the performance of the new process.

Sticking the landing

Have you ever tried to watch a game without a scoreboard? How would you know who was winning? Or how much time was left?

It’s the same with process work.

How does your team know how they’re doing? How do you stay aware of how the new process is performing?

By making the data visible.

Keeping an eye on Process Performance can be done with a single metric — you need to focus on one thing. If the goal was to reduce defects, then the single metric would be tracking the daily percentage of defects. A great way to measure success is with a Control Chart.

Control Charts are time charts. You might know them as Line Charts or Run Charts. They include a measure of variation so they are often referred to as “Run Charts that went to college”. They can be created in Excel , but they can also be drawn by hand.

Teams often set up whiteboards in the shared workspace to track things like defects. People can rotate responsibility for updating the chart. If people can see the measure and are responsible for it—they pay attention to it. What gets measured gets managed.

The Control Chart Template is embedded in the checklist for the Control Phase.

Process Improvement is a mainstay of Operational Excellence and checklists are simple but effective ways to make sure you get the outcomes you want. The following quote comes from the interim CEO/President of the Association for Manufacturing Excellence ( AME ).

“ I am a big fan of checklists for ensuring quality at the source. They serve an important purpose in reminding us of all that’s needed in a particular process or project. Without checklists, we risk missing or overlooking something by mistake. Checklists work best when ticking off items as they are completed, not en masse once the entire project is done. The key point is to use and follow them, not “pencil-whip” them from memory after the fact. While not foolproof, checklists can help us cover the details and result in more thorough, successful improvement efforts. ” – Jerry Wright , President, AME

Checklists have transformed healthcare, aviation, and countless other industries. Run this Process Street DMAIC Tollgate Checklist and make sure your next improvement effort gets great results.

Process Street is a powerful piece of workflow software that lets you crush the human error in your organization.

By creating process templates (like the free DMAIC checklist in this post) you can give your whole team a central location for them to see what they have to do, and how exactly they should do it.

No more confusion, no more errors.

Take advantage of our powerful feature set to create superpowered checklists, including:

- Form fields

- Conditional logic

- Variable user permission levels

- Exporting and printing templates

- And much, much more!

Check out our intro webinar to see the app in action!

Stop leaving the success of your processes up to chance. Get started with a free trial of Process Street today!

How do you manage quality control in your business? Let us know in the comments!

Get our posts & product updates earlier by simply subscribing

Ben Mulholland

Ben Mulholland is an Editor at Process Street , and winds down with a casual article or two on Mulholland Writing . Find him on Twitter here .

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Take control of your workflows today

- > Lean Six Sigma: Definition, Principles, and Benefits

Lean Six Sigma: Definition, Principles, and Benefits

Posted by Danielle Yoon

Nov 20, 2023 10:13:00 AM

Lean Six Sigma, a secret weapon of some of the world's most successful companies, is not just a data-driven methodology; it's a revolution in how we approach business processes. Whether you're an executive, a manager, or simply someone with a curious mind, Lean Six Sigma is the key to unlocking the secrets of peak performance.

This article will look into the heart of this transformative force. We'll cover Lean Six Sigma principles, the keys to successful Six Sigma projects, and the benefits you can expect to enjoy.

What Is Lean Six Sigma?

Lean Six Sigma is a data-driven process improvement methodology and project management structure that combines two powerful approaches: "Lean," which focuses on reducing waste and inefficiency, and "Six Sigma," which aims to minimize defects and variations in processes. This combined approach is used to streamline operations, enhance quality, and increase organizational efficiency.

One of the earliest adopters of Lean Six Sigma was Motorola in the 1980s. They successfully reduced defects in their manufacturing processes , and it is said that their efforts saved over $16 billion. Their breakthrough inspired many other manufacturing companies, like General Electric, which credits Lean Six Sigma projects with saving them billions and improving product quality. It soon became a cornerstone of operational excellence in the manufacturing industry, proving that it wasn't just a passing trend.

In healthcare , where patient safety is paramount, Lean Six Sigma has played a crucial role. By streamlining processes and reducing errors, some organizations enhance patient satisfaction and reduce costs. This shows how Lean Six Sigma's principles could be applied outside traditional business settings, revolutionizing healthcare management and patient outcomes.

Even the financial sector , often associated with complex transactions, embraced Lean Six Sigma. A notable example is Bank of America, which used Lean Six Sigma to streamline its mortgage operations. They reduced processing times, minimized errors, and improved customer service. This demonstrated the adaptability of Lean Six Sigma principles across diverse sectors, proving its effectiveness in optimizing financial services.

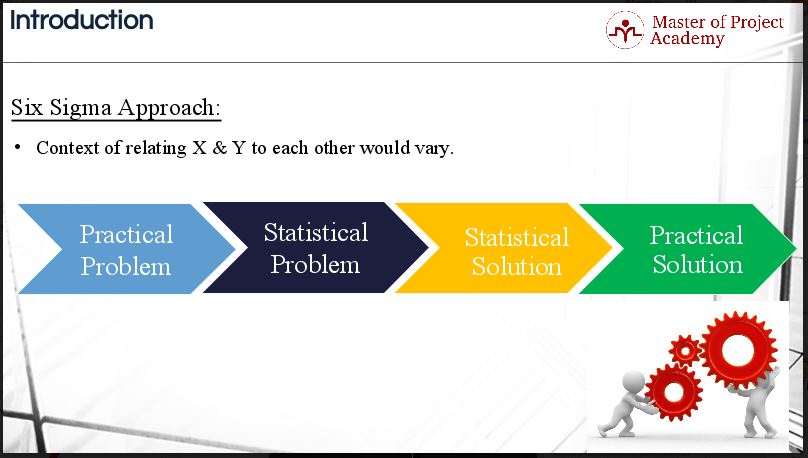

The Six Sigma Methodology

The DMAIC process in Lean Six Sigma (Define, Measure, Analyze, Improve, Control) is vital for structured problem-solving and continuous improvement. It provides a systematic approach to identifying issues, measuring their impact, analyzing root causes, implementing solutions, and maintaining long-term control over processes, ensuring sustainable results. DMAIC fosters data-driven decision-making, reduces errors, and maximizes efficiency, making it a cornerstone of Lean Six Sigma's success in achieving quality and process improvements.

Several best practices and Sigma tools support the effective implementation of DMAIC in the Lean Six Sigma methodology.

Clear Project Definition: Start with a well-defined problem statement and project scope in the "Define" phase. This clarity ensures that the team's efforts remain focused on the most critical issues and opportunities for improvement.

Data Collection and Analysis: In the "Measure" phase, gather relevant data systematically and ensure its accuracy. Employ statistical tools to quantify process performance, identify variations, and prioritize areas that need improvement.

Root Cause Analysis : During the "Analyze" phase, dig deep to identify the root causes of issues rather than addressing symptoms. Techniques like Fishbone diagrams and the " 5 Whys " can help uncover underlying problems.

Solution Testing: In the "Improve" phase, pilot test proposed solutions on a small scale before full implementation. This minimizes risks and allows for adjustments before rolling out changes across the organization.

Change Management: Implementing improvements using the Lean method can face resistance. Effective change management strategies, such as involving key stakeholders and communicating the benefits of the changes, are essential in the "Control" phase to ensure sustainable results.

Continuous Monitoring: Develop control plans and establish Key Performance Indicators (KPIs) to monitor process performance over time. Regularly review data and conduct periodic audits to ensure that the improvements are maintained.