- Work & Careers

- Life & Arts

Become an FT subscriber

Try unlimited access Only $1 for 4 weeks

Then $75 per month. Complete digital access to quality FT journalism on any device. Cancel anytime during your trial.

- Global news & analysis

- Expert opinion

- Special features

- FirstFT newsletter

- Videos & Podcasts

- Android & iOS app

- FT Edit app

- 10 gift articles per month

Explore more offers.

Standard digital.

- FT Digital Edition

Premium Digital

Print + premium digital, ft professional, weekend print + standard digital, weekend print + premium digital.

Essential digital access to quality FT journalism on any device. Pay a year upfront and save 20%.

- Global news & analysis

- Exclusive FT analysis

- FT App on Android & iOS

- FirstFT: the day's biggest stories

- 20+ curated newsletters

- Follow topics & set alerts with myFT

- FT Videos & Podcasts

- 20 monthly gift articles to share

- Lex: FT's flagship investment column

- 15+ Premium newsletters by leading experts

- FT Digital Edition: our digitised print edition

- Weekday Print Edition

- Videos & Podcasts

- Premium newsletters

- 10 additional gift articles per month

- FT Weekend Print delivery

- Everything in Standard Digital

- Everything in Premium Digital

Complete digital access to quality FT journalism with expert analysis from industry leaders. Pay a year upfront and save 20%.

- 10 monthly gift articles to share

- Everything in Print

- Make and share highlights

- FT Workspace

- Markets data widget

- Subscription Manager

- Workflow integrations

- Occasional readers go free

- Volume discount

Terms & Conditions apply

Explore our full range of subscriptions.

Why the ft.

See why over a million readers pay to read the Financial Times.

International Edition

Outsourcing to China: Pros, cons & best practices

Outsourcing to China is a strategy that has led several businesses to success.

However, it can also lead to financial losses if done with insufficient information and poor planning.

But, don’t worry!

We’ll guide you through it.

In this article, we’ll discuss the 9 key benefits and 4 major challenges of outsourcing to China. We’ll also go over a few steps you can take to outsource to China successfully.

This article includes:

(Click on the links to go to a particular section)

- 9 Key Benefits of Outsourcing to China

- 4 Major Challenges of Outsourcing to China

- Outsourcing to China the Right Way

Let’s get started.

Learn more about outsourcing before you go further.

9 key benefits of outsourcing to China

According to Grand View Research, a business consulting firm, China’s outsourcing industry had contracts worth around $223.7 billion in 2019.

In fact, American companies like Amazon, Apple, Pfizer, and many others have outsourced to China.

The country is a popular global outsourcing hub because it offers these benefits:

1. Cheaper labor

China’s low labor costs are a huge selling point for labor-intensive industries.

As of July 2021, the average wage in China is 29,300 Chinese Yuan (CNY) per month (approximately 4,530 US Dollars, according to the exchange rate in July 2021). This means that their average salary is almost half that in the United States (about $7,900/month).

Businesses can further access lower labor costs by outsourcing to developing cities like Wuxi, Jiangsu, Chengdu, and Sichuan instead of larger cities like Beijing.

In addition, low labor costs can help companies with a high turnover rate (percentage of employees leaving the company).

By outsourcing to China, those companies may spend less capital on hiring and training employees. This way, they’ll lose less when an employee resigns.

2. Cheap products

China houses the world’s largest manufacturing sector and produced 28.7% of the global manufacturing output in 2019. This means that your business in China doesn’t have to import these products, helping you avoid import tariffs.

Additionally, the business ecosystem in Chinese cities has enabled manufacturing companies to build products at lower costs.

These cities have cultivated a system that supports the China manufacturing supply chain . A Chinese factory can easily access component manufacturers, low-cost workers, technical workforce, assembly suppliers, and customers.

This arrangement reduces the cost of production, enabling the manufacturers to sell products at lower prices.

3. Frees up more time to focus on core competency

China has the talent and resources to handle IT, customer service, manufacturing, accounting, and more. This means that you can outsource almost any part of your business confidently to the country.

By outsourcing, you’ll have more time to concentrate on expanding your business or optimizing current business processes .

Your in-house team can focus on core competencies , like team building, leadership, and product development, instead of doing paperwork or other mundane tasks. An increase in performance in core competencies can help you increase your competitiveness and profits.

4. Increased flexibility

Most companies outsource manufacturing, production, bookkeeping, and other non-core business processes to contractors for the ease of scaling up and down.

For example, a western company outsourcing manufacturing to a Chinese manufacturer can reduce or increase its orders without any legal issues.

Contract manufacturing service providers usually have more than one client and manufacture stock for all of them. As a result, they can arrange additional products whenever you need them.

Similarly, they can manage excess production by manufacturing less for the next order. Manufacturing contractors may agree to immediate scale-downs more readily, giving you the flexibility to reduce your production quickly.

Moreover, China has a large potential workforce which enables Chinese contractors to scale up productions cheaply .

5. Access to mass markets

China is geographically situated between the Asian and European markets and is an active participant in world trade. As a result, outsourcing processes to this Asian country can give you easy access to profitable markets.

Additionally, since China itself is a huge market , offshoring to the country can create huge opportunities for companies. The low labor wage, resource-intensive manufacturing, and exports make offshoring to China a profitable option.

6. Fast-paced innovations and research

According to the Global Innovation Index (GII) 2020, an annual ranking of countries based on their innovations, China ranks 14th among 113 countries. It comes before countries like Japan, the Philippines, and India.

Additionally, the GII also said that Chinese companies are on par with the best Switzerland, Sweden, and US companies when it comes to innovation.

This is because China houses tons of innovative companies, including high-tech startups like Weltmeister, an electric car brand.

According to a list of the 50 most innovative companies published by Boston’s Consulting Group (BCG), Huawei (a popular Chinese multinational smartphone company) ranks 8th in the world. The list also includes Alibaba (14th), Lenovo (25th), Tencent (26th), and Xiaomi (31st).

Outsourcing to a country with huge research potential, like China, can give you quick and easy access to technology. This will provide you with a competitive advantage over your competitors from other countries.

7. Supportive government policies

The Chinese government tends to welcome any foreign company that shows an interest in outsourcing.

Additionally, China continually amends its outsourcing laws and works towards improving its infrastructure to ensure smooth outsourcing. In fact, the country spent around 10 times more on infrastructure than the US in 2018.

But China’s investments in infrastructure stretch beyond bridges and railways. The country has also successfully developed digital infrastructure, particularly broadband and digital payment systems.

8. Great startup culture

Startups offer business agility, access to new technology, insight into target markets, and customer-centric innovations.

As a result, outsourcing to the Chinese economy with tons of startups will get you access to resources that can help you overtake your competitors.

In addition, your business can get services or products from startups at lower costs when compared to established companies.

Chinese cities like Hong Kong , Shanghai, and Chengdu help high-tech startups flourish. They do this through initiatives that improve infrastructure and by giving access to top talent.

Additionally, these cities are politically stable with an open culture due to globalization. Such an adaptable and friendly environment makes outsourcing convenient and pleasant.

9. Access to a skilled workforce

China saw 7.6 million students graduate from its universities in 2018, which is almost double of all degrees earned at American universities.

On top of that, China established a Thousand Talent Program, which aims to attract scientific talent to the country. This plan recruited over 7,000 scientists to the country, further increasing their research and talent pool quality.

4 major challenges of outsourcing to China

Let’s look at a few difficulties you might face while outsourcing to China:

1. Low service or product quality

The quality of Chinese products is sometimes lower when compared to foreign products.

Often, Chinese products don’t meet international standards and aren’t valued much despite their affordability.

To avoid this, outsourcing companies must stay vigilant to ensure that their products are of high quality. You can do this by conducting regular quality control reviews or hiring an agent in China to run inspections for you.

2. Different IPR laws

IPR ( Intellectual Property Rights ) laws differ from country to country.

You’ll need to do some research on China’s copyright and trademark system, especially when the service provider has access to your products, designs, and more.

Even though the Chinese government and most outsourcing companies adopt strict IPR measures, manufacturers could make and sell copies of your new products at lower prices.

If you’re concerned about protecting your intellectual property, you could draft an NNN (non-disclosure, non-use, non-circumvention) agreement instead of the traditional NDA (Non-disclosure Agreement).

An NDA focuses only on preventing the service provider from releasing your trade secrets to the public. In contrast, a NNN agreement prevents your employees from disclosing, using, or selling your trade secrets.

3. Language barriers

A Chinese company may find it hard to employ citizens with decent proficiency in English.

Outsourcing to such service providers can make it difficult for your employees to communicate with the outsourced company, interrupting work completion.

In addition, if you outsource your customer support processes, your customers might not be able to communicate with your Chinese agents due to language barriers.

4. Time-consuming set up

Each Chinese city has a different technical and outsourcing potential. The wrong outsourcing destination can lead to a lengthy setup procedure and a long supply chain.

That being the case, you need to consider the strengths and weaknesses of cities before you outsource. For example, you should know how far your service provider is from your target market, the availability of required talent, the cost of resources, etc.

For example, it’s best to start your company in Dalian (a port city) if you want to export products overseas. Setting it up in a city like Beijing will cost you a lot of money in transportation.

Outsourcing to China the right way

Let’s look at a few tips that will help you outsource to China successfully:

1. Contact a local sourcing agent

A local sourcing agent (a third party that helps you with major outsourcing decisions) can help you select the right Chinese supplier and prevent you from investing money in the wrong place.

In addition, they can guide you on outsourcing to a suitable city, legal outsourcing procedures, and how to kick-start your business.

However, hiring a local agent isn’t a mandatory step for successful outsourcing to China.

2. Verify your supplier’s credentials

Once you’ve shortlisted a few outsourcing providers, verify their credentials .

Recognize your outsourcing needs as China has many talented manufacturers and traders. You should choose a suitable outsourcing partner depending on your business needs.

While verifying supplier’s credentials, you should:

- Check whether the supplier can produce according to your requirements. Make sure that they will be able to supply products if you decide to scale up.

- Cross-check the information they provide. An easy way to do this is by checking their website.

- Ask for their business license, international trade certificate, customs registration certificate, and VAT invoices. Ensure these documents are genuine by consulting a reliable source.

- Confirm the supplier’s name is the same across all the documents.

- If possible, visit the factory or office before you finalize everything. You could also ask a representative to make the visits on your behalf.

3. Draft agreements carefully

Outsourcing agreements must define the specifics of the arrangement precisely.

For example, if you’re outsourcing production, the agreement should cover aspects like the price per product, volume, mode, etc.

Similarly, you need to mention minimum productivity, working hours, KPIs (Key Performance Indicator), and more, when you’re going over your service outsourcing process.

And irrespective of the nature of outsourced tasks, the agreement must specify ways to resolve disputes, agreement dissolution, and other legal matters. More importantly, ensure that the meaning of the agreement doesn’t change when translated to Mandarin or English.

4. Clearly define product/service specifications

To avoid issues in the future, you’ll need to explain what you expect from your outsourcing partner clearly. This includes your product’s specifications.

You should list down and explain even the minute details, like raw material or service quality. You should also conduct regular inspections to check whether all manufacturing processes or service updates are implemented correctly.

5. Gain support from your internal team

Once your company decides to outsource to a Chinese firm, you need to inform your internal team about it.

To do this, you’ll need to explain why you’ve decided to outsource to China and how each department will benefit from it. You should also clarify the roles and responsibilities of each team member so that they know how to go about their outsourcing tasks.

Without a clear understanding of their duties, they may get confused and feel disengaged.

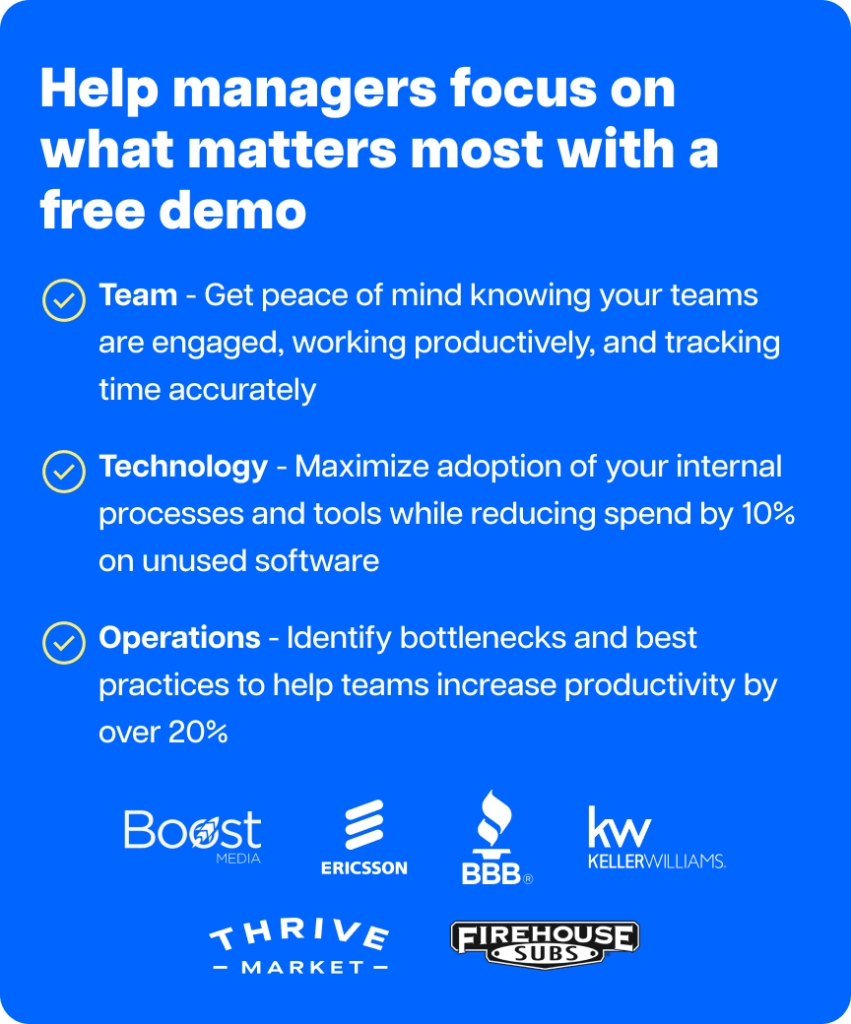

6. Use performance monitoring software

Monitoring your outsourcing partner’s employees can be challenging, especially when you’re in a different country.

To control absenteeism, distractions and ensure that they work productively, you need to use a performance monitoring tool like Time Doctor .

What’s Time Doctor?

Time Doctor is a powerful employee performance and productivity management tool used by small companies like Thrive Market, as well as large firms like Ericsson. This tool helps companies track and record the activities of their employees when they work.

With Time Doctor, you can:

- Track the time employees work using an interactive time tracker .

- Manage their performance based on real-time productivity reports .

- Control distractions using an idle time pop-up feature.

- Assign projects and tasks to outsourced employees.

- Schedule shifts efficiently from any corner of the world.

Additionally, you can keep track of billable hours and use Time Doctor’s payroll feature to pay your outsourced team through Wise, PayPay, or Gusto.

Wrapping up

Outsourcing to China is a cost-saving strategy that can be a turning point in your business. You can use the exposure you get in the country to grow your business across the globe.

But to do this, you have to do your research, choose the right outsourcing partner, and put the right processes in place.

To ensure that you meet a positive turning point, consider the pros, cons, and tips mentioned in this article before making a decision.

View a free demo of Time Doctor

Andy is a technology & marketing leader who has delivered award-winning and world-first experiences.

The Great Resignation: Why Americans are quitting their jobs in record numbers

The top 13 websites to find talented developers online, related posts, kpo industry in india: pros/cons & top outsourcing services, kpo philippines: top services, benefits, service providers, kpo directory: 13 top global knowledge service providers, top 10 kpo companies in india in 2024, the 2024 clear & simple guide to kpo services, 14 top kpo companies in 2024.

Getting sourcing right in China

Five years ago , flights to China from Europe, North America, and Japan were filled with sales managers seeking markets for their companies' products. Today those flights have as many procurement and supply chain managers as marketers. Leading Western and Japanese companies are no less eager to source Chinese parts and products for developed markets than to sell into one of the world's fastest-growing economies.

The country's rapid rise as a low-cost manufacturing hub is what draws these men and women. Retailing giants such as Carrefour and Wal-Mart Stores are going to China to buy an expanding range of goods—from televisions and tools to clothing and crockery—for 25 to 50 percent less than the cost of comparable goods made in developed countries. Automakers around the world are pressing their leading suppliers to open operations in China or are themselves trying to source components there (see " Global sourcing in the auto industry "). Although the proportion of goods sourced in this way remains small even for companies that began buying Chinese-made goods more than a decade ago, the pace is accelerating, particularly in high technology, consumer electronics, retailing, and some industrial goods. The result is that leaders in these sectors are gaining cost advantages over competitors that source components or finished goods mostly in the developed world.

Although the opportunity is certainly enticing, it can be hard to get the many pieces of a procurement operation in China right. Lessons learned ten years ago by companies as they set up purchasing operations in other low-cost regions, such as Brazil and Mexico, travel only so far. Finding high-quality suppliers and negotiating agreements with them is a problem that companies face in any new locale, for example, but the greater geographic distance between suppliers in China and headquarters makes the job tougher for companies based in North and South America. Another challenge is coming to terms with the widespread use of sourcing agents, which can be a boon or a bane, depending on what individual companies need. Then too there are issues—such as sorting out logistics, securing reliable broadband connections, and cultural and language differences—that companies rarely face at home.

Those that do establish successful sourcing operations in China concentrate on a few fundamentals. They make changes at the home office to address the organizational inertia that can slow down the introduction of a purchasing program in China. They attend to the details, monitoring suppliers as closely as possible. And like one Western company that set and exceeded a $100 million first-year target, they establish a firm goal for sourcing and do what they must to achieve it. Such companies also learn to build local capabilities by staffing teams carefully and using third parties to support them in important tasks, such as quality assurance and logistics.

In these ways, companies lay a foundation they can use to relocate bigger and more crucial pieces of their supply chain operations. They gain cost and operational advantages that competitors can't match and capabilities that competitors can't easily replicate.

Opportunities and hurdles

Manufacturing accounted for 60 percent of China's GDP growth over the past decade. Multinationals set up operations there, and domestic companies expanded to make goods for export and to sell products and services to multinationals doing business in the country. But that was just the start of the boom.

Even though Ford Motor and General Motors have considerably beefed up their supply lines from China during the past few years, for example, those goods constitute only a fraction of the components used in their vehicles. If the two automakers sourced half of their basic parts (such as carpets, castings, electronics, tires, and wiring) from China, they could together save more than $10 billion a year. Both say that they expect to increase their purchases of Chinese-made parts vastly.

Companies in other sectors are also racing up the Chinese sourcing curve. Wal-Mart bought about $10 billion to $15 billion worth of goods from China in 2003 and hopes to almost double that amount by 2007. Other retailers, including Best Buy, Carrefour, and Tesco, have equally ambitious plans.

The potential is impressive, but so are the difficulties, ranging from intellectual-property infringements and customs delays to poor communication between headquarters and suppliers. Ford reportedly did not meet its target of sourcing $1 billion worth of components from China last year, largely because the job of evaluating suppliers and establishing supply chain connections was bigger than the company had thought. But these hurdles, while daunting, can be overcome. Our work with companies that source goods in China suggests that three important issues should be addressed at the outset; other problems can be resolved later.

Inertia at headquarters

One of the biggest barriers to a Chinese sourcing program is resistance from middle managers at home, who often have a limited perspective. If their performance is measured on inventory turns, for example, they might worry that distant and uncertain supply lines will require them to hold larger inventories, thereby driving up costs and reducing turns. Similarly, logistics managers, who are evaluated on their ability to economize, warn that using far-flung suppliers will push up costs. Procurement managers wave the yellow flag about the quality of goods, while product designers, manufacturing chiefs, and plant managers all have objections of their own.

And they are right, from their specific points of view. Inventory and logistics costs will rise. Adjustments will be needed to deal with the new risks of managing suppliers in China. But companies that succeed there have demonstrated that the benefits of lower-cost purchasing almost always outweigh the increase in operational costs and risks. Even after accounting for them, one retailer recorded overall savings of more than 20 percent in its sourcing operation.

Managers at such companies see the bigger picture. They commit the time needed to make the case for change, sell it internally, and transform organizational structures, incentives, and performance measures. And as we have seen in our own work, there is also clear direction from the top. Without unambiguous support from senior executives, programs languish when procurement departments or operational managers try to implement them.

Executives can overcome resistance to change by making a persuasive case for it. Some sponsor efforts to develop total-cost-of-ownership models that show whether the benefits of sourcing in China outweigh the additional logistics costs, lower inventory turns, and risks to quality (exhibit). At one high-tech company, for instance, managers from functions such as logistics and procurement worked with the CFO to create such a model. This exercise not only encouraged them to buy into the final assessment but also helped middle managers identify cross-functional sourcing issues, including how to get the logistics, inventory, and marketing teams working together to manage longer supply chains.

In addition, executives must find ways to minimize the pain of process changes and to make them acceptable quickly. One manufacturer began by using its existing processes to select, approve, negotiate with, and manage vendors instead of setting up a special Chinese initiative staffed by employees whose powers usurped the authority of sourcing and product managers. Processes and sourcing roles changed only after the company became comfortable working with Chinese suppliers. This manufacturer believes that the experiment helped its managers design a better sourcing program by allowing them to learn gradually about new approaches to purchasing, logistics, selecting vendors, and negotiations.

As a short-term measure, companies might redesign their performance incentives in order to encourage purchasing managers to buy goods from China. One retailer introduced "incubation" incentives to motivate its buyers, rewarding them with bonuses for the volume of products they sourced there.

Building capabilities

To source goods directly from China, a company must learn a set of basic capabilities. These include ensuring quality and control (evaluating a supplier's ability to meet requirements, for example), testing preproduction prototypes or samples, and assessing packing procedures. Logistics activities such as satisfying customs regulations and arranging shipments are important as well.

During the transition phase, a company might work with China-based agents—trading intermediaries that buy and ship goods—until it had identified and trained the internal talent needed to deal directly with Chinese suppliers. The first of the intermediaries to go will be those that merely buy and sell, because they offer the least added value. Naturally, these agents are likely to pull out all the stops to keep their treasured positions by arguing that they understand local business practices better than overseas managers can. They also claim to do the heavy lifting so foreign companies don't have to spend time trawling for suppliers, negotiating deals, and establishing infrastructure and organizations to manage supply. Ultimately, they will contend, they can "do a better job for you than you can do for yourself here."

In our experience, foreign companies can actually learn to do quite well for themselves, whatever the agents' persuasive claims to the contrary. The real issue is how to decide when to use third parties. If a company sources more than $100 million a year in goods from China, it makes economic sense to have a unit there that can go directly to suppliers, because the cost of running a direct-procurement operation is a third or less of what agents charge. But though they should generally be used as sparingly as possible and according to strict criteria, there are reasons to take advantage of the specialized services that some of them offer: certain agents are skilled at handling delicate materials or complex product categories, for example, or have exclusive rights to particular factories. Moreover, a steady flow of agents through a procurement office can promote market-led innovation and provide useful information about changes in the supplier base.

Direct sourcing may be cost-effective even if a company procures as little as $40 million a year in goods. In this case, however, it can turn to an array of specialist third-party providers that help it identify reliable suppliers, provide quality assurance and control, and perform logistics tasks. Combining in-house activity with the use of third parties permits a company with lower levels of direct sourcing to set up its own office in China and start reducing its reliance on intermediaries while capturing significant savings.

Companies that set up their own procurement operations should focus on building their leadership teams. Four important posts must be filled: the heads of the office, procurement and merchandising, quality assurance and control, and logistics. The ideal candidate for each role will have a knowledge of the company, the industry, and China—and be fluent in Mandarin. As many companies have discovered, the perfect candidate rarely exists. If no single person can be found for a job, it might be necessary to build a team that amalgamates these qualities.

Attention to detail

Direct sourcing is a complicated set of activities involving many detailed decisions, from selecting suppliers to managing production, quality, inventory, and logistics. Executives know that companies can stumble in any of these activities as they expand their sourcing options around the world. What surprises executives about sourcing in China is the number of details that can go wrong and the effort required to hold a program together. Companies find that they have to pay much more attention than expected to monitoring their suppliers' flow processes—working back from expected delivery dates to check that suppliers receive raw materials on time and meet every subsequent milestone until the products ship. In other words, you have to be there. Without hands-on supervision and quick action when milestones are missed, companies face delays. Intensive monitoring is required in every industry and with most suppliers in China.

This level of attention, though not unheard-of elsewhere, isn't common. What makes China particularly tricky is geographic distance. Managers must not only spend more time on tactical details but also—particularly in the case of North and South American corporations—must do so in vexingly different time zones: they might have to get on the telephone in the middle of the night to communicate with colleagues half a world away. Companies that haven't mastered the details incur shipment delays and additional costs. More important, some find that because they are constantly fighting fires, it is difficult to scale up the sourcing they do in China.

Setting the stage

Solving the leadership conundrum at home and establishing effective sourcing capabilities in China are today's challenges. Companies that get it right will be in a position to establish a long-term source of competitive advantage by taking the operations they build in China today to the next level.

One way would be developing additional capabilities in China to cut cycle times. Upstream activities such as the approval of prototypes and samples could be moved there and kept close to the manufacturing operations of suppliers, thus reducing the need to rely on headquarters. Streamlining this back-and-forth process could trim by a third the time—currently half a year or more in many cases—needed to develop and make new products. Bringing them to market more quickly can have a tremendous impact on a company's economics by improving its understanding of consumers, increasing the accuracy of forecasts, and reducing stockouts and markdowns. European "fast-fashion" retailers such as H&M and Zara have shown the possibilities of this model close to home. The next such opportunity is applying it to products from China.

Another possibility would be to relocate postproduction tasks there. Attaching price labels, ironing and hanging garments, packing consumer electronics product kits, repacking pallets for delivery to points of sale—all of these activities, currently undertaken in Western warehouses, could be completed more cheaply in China.

Shifting responsibility for procurement or even warehouse activities is a challenge. Not least important, a company that goes down this road will find it necessary to create a local staff that can make the correct decisions. Talented engineers and designers will have to be moved from headquarters or recruited and trained in China. More problematic still, headquarters staff will be required to surrender some decision-making power to counterparts based in that country. Processes and IT will have to change so that people can share information and images (for example, of designs or samples) and feel comfortable about decisions made under the new arrangements.

Procurement practices may well prove to be a source of competitive advantage. Companies that have strong ties to suppliers in China could work with them to adopt best practices that cut operating costs and improve lead times, as Toyota Motor has done in past years. Manufacturers, which already know how to run factories efficiently, will find this approach easier to implement than retailers will. Although retailers will have to learn new skills, they won't find it beyond their powers. Companies could also introduce sophisticated procurement tools, such as clean-sheet costing, to drive down supply costs further and to set targets for future cost benefits that could be shared by supplier and buyer.

But efforts to build for tomorrow must begin today. The significant competitive operating advantages that companies could begin to harvest in China within three to five years will be possible only for those that establish the proper fundamentals right away.

Robert Campbell is a consultant and Jimmy Hexter is a principal in McKinsey's Beijing office; Karen Yin is a consultant in the Shanghai office.

Explore a career with us

Hey there! 👋 Looking to increase your team’s productivity?

Get a 7-day free FULL FEATURE trial of Insightful today. Insightful makes your team productive, efficient and accountable – wherever they work. Ranked #1 for ease-of-use and results. Try it today!

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Unlock the Benefits of Outsourcing to China: A Comprehensive Guide

Explore the intricacies of outsourcing in China, from salary trends to legal considerations. Discover how Insightful, a leading working remotely software, can help manage outsourced teams effectively.

.jpg)

Speak with a Productivity Expert

Give us 30 minutes and we’ll show you how we can help you achieve better results.

China is emerging as a significant player in the outsourcing industry, rivaling traditional powerhouses such as Indonesia and the Philippines, attracting businesses worldwide with its highly skilled talent pool and cost-effective solutions.

Numerous global companies have chosen to outsource in China, including Apple, HP, Dell, Adidas, and Nike - showcasing a growing trend among international businesses to take advantage of China's outsourcing capabilities.

In this comprehensive guide, we will delve into the intricacies of outsourcing in China, including salary trends, top industries, and best practices for managing outsourced teams. We will also explore how a work time cloud monitoring app, such as Insightful, can help you effectively manage your outsourced workforce.

Effectively Monitor Outsourced Teams with Insightful

Understanding the chinese yuan: a quick currency comparison.

China's currency, the Chinese Yuan Renminbi (CNY), plays a crucial role in the country's attractiveness for outsourcing. Here's a comparison of the Chinese Yuan against other major currencies:

1 US Dollar = 6.95 Chinese Yuan

1 Euro = 7.56 Chinese Yuan

1 Pound = 8.67 Chinese Yuan

The average monthly salary in China is around CNY 8,242 ($1,278 USD). While this may appear high compared to some other Asian countries, the cost of living varies significantly across China, with living costs in cities like Beijing and Shanghai being higher than the national average.

Exploring the Salary Landscape in China

Salaries in China vary widely based on factors such as job title, education level, and location. High-paying roles typically include IT Managers, Financial Analysts, and Engineers, while low-paying roles might include Customer Service Representatives and Data Entry Specialists.

There is a notable gender wage gap in China, with men often earning more than women. Bonuses and incentives are common in China and can greatly influence the total compensation.

The Top 3 Outsourced Industries in China

The top three outsourced industries in China are:

Manufacturing

One of the primary reasons China is often referred to as "the world's factory" is its unparalleled dominance in the manufacturing sector. Over the last few decades, China has invested heavily in its manufacturing infrastructure, leading to the development of a complex supply chain and logistics network that is hard to rival.

The sector is supported by a massive workforce, advanced machinery, and efficient production techniques. Outsourcing manufacturing to China enables businesses to leverage these resources for a wide range of products, from electronics and automobiles to textiles and consumer goods.

IT and Software Development

China's emphasis on STEM (Science, Technology, Engineering, and Mathematics) education has resulted in a vast pool of highly skilled IT professionals. The country's universities churn out millions of engineering and computer science graduates each year, many of whom are well-versed in the latest technologies and programming languages.

This makes China an attractive destination for outsourcing IT and software development services. From software programming and app development to artificial intelligence and machine learning, Chinese IT professionals are capable of handling a wide range of tasks.

Customer Service

Customer service is another area where China shines in the outsourcing industry. One of the key reasons for this is the availability of a large, multilingual talent pool. As more Chinese students study abroad and return home, and as English education becomes more prevalent in Chinese schools, there is an increasing number of Chinese workers proficient in English and other languages.

This enables them to handle customer service operations for global businesses effectively. Moreover, the Chinese government has been actively promoting the service sector, including customer service, as a part of its economic restructuring efforts, leading to better training programs and infrastructure for customer service operations.

The Benefits of Outsourcing to China

Outsourcing to China can provide businesses with many potential benefits:

- Access to a vast, highly skilled talent pool: China's vast population and emphasis on STEM education creates a massive pool of skilled professionals in sectors like manufacturing, IT, and customer service.

- Competitive pricing: Despite rising costs, China maintains competitive prices for many types of work, particularly in manufacturing, offering businesses excellent value for money.

- Advanced infrastructure: China's significant investment in physical and technological infrastructure positions it as a global leader in areas like e-commerce, mobile technology, and AI.

- Rapid scalability: The extensive workforce and comprehensive infrastructure in China allow businesses to scale their operations quickly, accommodating growth and fluctuating demand levels.

- Government support: The Chinese government encourages the outsourcing industry and foreign investment, making the process smoother and more attractive for foreign businesses.

Communication and Collaboration: The Key to Success with China Outsourcing Partners

Effective communication and collaboration are paramount for any prosperous outsourcing partnership. When working with an outsourced team in China, consider the following points:

- Time Zones: China operates on China Standard Time (CST), which might be considerably different from your own. Schedule meetings and deadlines with this in mind to ensure smooth collaboration and prompt project completion.

- Language: While English is taught in schools and is commonly used in the business world in China, communication should be clear and concise. Avoid using idioms or colloquial phrases that might lead to misunderstandings.

- Tools and Technology: To ensure seamless communication and collaboration, familiarize yourself with the digital tools widely used in China such as WeChat, DingTalk, and Alibaba's Aliyun. These platforms could be pivotal in facilitating effective communication with your Chinese counterparts.

- Building Relationships: Known as "Guanxi," relationship-building is a crucial aspect of Chinese business culture. Investing time in building personal relationships can result in a more harmonious and effective working relationship with your Chinese outsourced team.

Legal and Compliance Considerations for Outsourcing to China

Outsourcing can provide several advantages to businesses, including cost savings and access to a diverse, skilled workforce. However, when outsourcing to China, it's critical to consider the legal and compliance aspects to avoid potential pitfalls. Below are some key factors to bear in mind:

Data Protection Laws

Ensure your Chinese outsourcing partner adheres to data protection laws and has robust measures in place to safeguard sensitive data. For instance, China's Cybersecurity Law mandates the protection of personal data and sets out specific requirements for data privacy. For clients based in the European Union, GDPR compliance is equally critical.

Intellectual Property Rights

Securing your company's intellectual property is crucial. Engage legal experts to draft agreements that clearly define the ownership and usage of intellectual property generated during the outsourcing process. Be aware of China's IP laws and regulations, including the Patent Law of the People's Republic of China and the Copyright Law of the People's Republic of China, to ensure your IP rights are protected.

Chinese Labor Laws and Regulations

Verify that your outsourcing partner adheres to Chinese labor laws and regulations, such as minimum wage, working hours, and employee benefits. Familiarize yourself with local labor laws like the Labor Law of the People's Republic of China and the Labor Contract Law of the People's Republic of China, to ensure your outsourcing partner's compliance.

Tax Implications

Engage with tax professionals to understand the potential tax implications of outsourcing to China, including any relevant taxes or double taxation agreements. China has different tax rates depending on the services involved, so be aware of any potential tax liabilities.

Understanding the Cultural Differences of Your Outsourced Chinese Teams

Working with teams from different cultural backgrounds can be enriching, but it's crucial to understand and respect cultural differences. When working with Chinese teams, consider the following cultural aspects:

Family and Relationships

Chinese culture places significant emphasis on family and personal relationships. This concept extends to the workplace, where building strong relationships can lead to more effective collaborations. Take time to know your Chinese team members on a personal level and show sincere interest in their lives.

Hierarchy and Respect

Chinese culture is deeply rooted in Confucianism, which values hierarchy and respect for authority. This respect for hierarchy is reflected in the workplace, where decisions often flow from the top down. When communicating, ensure you're addressing the appropriate person within the organization, showing respect to leadership and acknowledging the hierarchical structure.

Religious and Philosophical Considerations

While China is officially atheistic, Buddhism, Taoism, and Confucianism have significantly influenced Chinese culture. Additionally, some Chinese follow Christianity or Islam. These belief systems may influence the worldview and practices of your Chinese team members. Be respectful of these beliefs and consider them when planning meetings or setting deadlines.

Indirect Communication

Chinese culture often favors indirect communication to maintain harmony and avoid confrontation. This approach can sometimes lead to misunderstandings with Western counterparts who are used to more direct communication. Be patient, read between the lines, and use tact and diplomacy when providing feedback.

Monitor Outsourced Teams’ Performance with Insightful

To effectively manage your outsourced team in China, you need tools for working remotely, software like Insightful can be invaluable in this case. Insightful provides:

- Employee Monitoring: Monitor your outsourced team's work activity in real-time, ensuring they stay on task and productive.

- Time Tracking: Track time spent on projects and tasks, enabling you to better allocate resources and manage budgets.

- Detailed Reports: Gain insights into your team's performance with detailed reports on work hours, task completion, and project progress.

Insightful helps teams improve productivity!

Recommended articles, hipaa compliance: security measures and tools to make sure you always pass your audit, why you should optimize your business processes, the strategic advantage of bpo partnership for remote companies, finding a perfect balance between overtime and part-time working, the top 5 performance review tips you need to use, how employers can overcome these 3 diversity recruiting challenges, related posts.

%20(5).png)

From Insight to Action: Leveraging People Analytics for Agile Workforce Management

Explore how leveraging people analytics and AI can transform your workforce enterprise and turn HR into a strategic powerhouse, enhancing decision-making and agility.

%20(1).png)

Data-Driven Productivity Insights: A Better Way to Improve Employee Well-Being

Discover how you can use employee tracking software to boost employee well-being and make your teams work better together.

Is Organizational Inertia Slowing Down Your Operations?

Is your organization stuck in a rut? Discover effective strategies to combat organizational inertia, embrace change, and enhance operational agility. Act now to revitalize your workplace and stay ahead in a dynamic business landscape. Find out how a computer monitoring app can offer a comprehensive overview of your workforce’s health.

Want your hybrid or remote team to be more productive?

Claim your free 7-Day full feature trial of Insightful today. Insightful’s actionable work insights make your team more productive, efficient and accountable.

Ready to Take Full Control Of Your Workplace?

Try the simplest solution today…

Rated 4.8 Stars on GetApp

Rated 4.8 Stars on Capterra

Subscribe to receive the latest blog posts to your inbox every week.

More than Half of Fortune 500 Executives are Facing the Same Issue

Double down on digital trends in bpo with insightful, data-powered leadership: bpo manager's handbook for success, innovate or stagnate: skyrocket your bpo efficiency with strategic synergy, related posts.

%20(2)%20(1).png)

Providing Chinese sourced high specification metal and plastic components and assemblies to both large & SME western customers

- Mar 2, 2021

Aerospace Ground Equipment

Industrial Spray Finishing OEM

Automotive aftermarket supplier

CHINA OUTSOURCING

For more information please contact us on + 44 (0) 1202 606141.

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

Alibaba and the Future of Business

Alibaba is not a retailer in the traditional sense. It doesn’t source or keep stock, and logistics services are carried out by third-party providers. Instead, Alibaba is what you get if you take all the functions associated with retail and coordinate them online into a sprawling, data-driven network of sellers, marketers, service providers, logistics companies, and manufacturers. Indeed, Alibaba does what Amazon, eBay, PayPal, Google, FedEx, all of the wholesalers, and a good portion of manufacturers in the U.S. do, with a healthy helping of financial services for garnish.

Alibaba achieves this by leveraging the new technologies of network coordination and data intelligence. It harnesses the efforts of thousands of Chinese businesses to create an ecosystem that is faster, smarter, and more efficient than traditional business infrastructures.

This is an emerging business model that Ming Zeng, the chair of Alibaba’s Academic Council, calls smart business. Players in the ecosystem share data and apply machine-learning technology to identify and better fulfill consumer needs. This article provides a framework for transforming a company into a smart business.

Lessons from China’s innovative digital giant

Idea in Brief

A new business model.

Alibaba is an example of tomorrow’s “smart business”: a tech-enabled platform that coordinates multiple business players in an ecosystem.

How It Works

Players in the ecosystem share data and apply machine-learning technology to identify and better fulfill consumer needs.

How to Build It

Automate decision making by:

• making sure every interaction yields as much data as possible

• ensuring that all business activities are mediated by software

• using APIs and other interface protocols to ensure smooth interaction among software systems

• applying machine learning to make sense of data in real time

Alibaba hit the headlines with the world’s biggest IPO in September 2014. Today, the company has a market cap among the global top 10, has surpassed Walmart in global sales, and has expanded into all the major markets in the world. Founder Jack Ma has become a household name.

- Ming Zeng is the chairman of the Academic Council of the Alibaba Group, an e-commerce, retail, and technology conglomerate, based in Hangzhou, China, and the author of Smart Business: What Alibaba’s Success Reveals About the Future of Strategy (Harvard Business Review Press, September 2018). He is also the dean of Hupan School of Entrepreneurship, a private business school founded by Alibaba chairman Jack Ma and other leading Chinese entrepreneurs in Hangzhou.

Partner Center

Switch language:

- Analyst Comment

Apple diversifies supply chain but keeps China at the center

- Share on Linkedin

- Share on Facebook

Apple is moving some production out of China to overcome operational, geopolitical, and regulatory hurdles. However, China remains the central production hub for its devices.

Apple employs an extensive list of outsourcing partners to supply and manufacture components used in iPhones, iPads, Macs, and wearable devices. In 2020, the vast majority (98%) of Apple’s direct spending on materials, manufacturing, and assembly went to 200 suppliers. The manufacturing facilities of 85% of these suppliers were in Asia.

Go deeper with GlobalData

Component Makers Sector Scorecard - Thematic Intelligence

Consumer electronics sector scorecard - thematic intelligence, premium insights.

The gold standard of business intelligence.

Find out more

Related Company Profiles

Mckinsey & co inc.

Out of the 30 countries where Apple devices were manufactured in 2020, six accounted for over 80% of annual production. China contributed 42%, followed by Japan (16%), the US (9%), Taiwan (6%), South Korea (5%), and Vietnam (4%). China’s leading position in Apple’s supply chain is attributable to several factors, including:

- the country’s massive industrial infrastructure,

- the availability of a large, affordable, and skilled labour force;

- the low cost of production compared to most other countries; and

- the ability of Chinese manufacturers to automate production lines.

According to Nikkei Asia, Apple increased its number of Chinese suppliers to 51 in 2020, up from 42 in 2018. Chinese suppliers typically offer high cost-efficiency and low turn-around time for production and increasingly focus on innovation.

China is a lucrative market for Apple

Greater China (which includes mainland China, Hong Kong, and Taiwan) is the third-largest market for Apple by revenue, behind the Americas and Europe. In the three months to the end of March 2021, Apple reported 87% year-on-year revenue growth in the region, significantly higher than in the Americas (35% growth) and Europe (56%).

China’s affluent consumer base is a critical driver for Apple’s revenue and brand growth. According to McKinsey, over 75% of China’s urban population will be considered middle class by 2022, and Chinese consumers will account for about 40% of global spending on luxury goods by 2025. Thus, China will be a vital market for Apple in the future.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

Chinese suppliers are expanding the Apple’s supply chain

The ongoing US-China trade war and rising labour costs in China have prompted Apple to move some production from China to Vietnam, Malaysia, and India. However, a large-scale shift is unlikely in the future as most countries do not offer China-like infrastructure, skilled labour, and governmental support. In addition, many components for Apple devices such as circuit boards, display panels, chargers, cables, and batteries are manufactured in China. Importing them to other countries before assembling the final devices would incur tariff expenses and labour training costs for Apple.

In 2019, Apple reportedly asked its suppliers to evaluate the cost of moving 15% to 30% of their production capacity from China to Southeast Asia. At the time of writing, several of Apple’s Chinese suppliers have production and assembly facilities in neighbouring countries. For instance, seven of nine Apple suppliers in India and 10 out of 23 in Vietnam are headquartered in China and Taiwan. This diversifies Apple’s supply chain while still keeping China at its center.

Apple will still explore revenue and other opportunities beyond China

Apple was expected to be heavily impacted by the COVID-19 lockdowns in China in early 2020. However, China’s quick recovery enabled the company to maintain shipments and launch new products amidst the pandemic. Apple’s supply chain has proved its resilience during uncertain times, but over-reliance on one country could prove to be a disaster in the future.

Apple must use other countries as complementary production hubs, explore ways to reduce production costs further, and mitigate tariff impositions on imported, explicitly China-made products. Domestic production will help alleviate a fair share of import tariffs, which will reduce the retail prices for Apple devices, making them more appealing to customers.

More Relevant

Microsoft offers relocation to China based AI staff as US crackdown continues

In data: china leads on building new chip fabs amid us china trade tensions, apple gets grant for tracking system with stylus and head-mounted device, industry takes: the importance of keeping healthcare businesses cybersecure, sign up for our daily news round-up.

Give your business an edge with our leading industry insights.

Sign up to the newsletter: In Brief

Your corporate email address, i would also like to subscribe to:.

Thematic Take (monthly)

I consent to Verdict Media Limited collecting my details provided via this form in accordance with Privacy Policy

Thank you for subscribing

View all newsletters from across the GlobalData Media network.

CodersOnFire—Blog

The Most Versatile Nearshore Software Development Company

How Apple Achieved a Legendary $2.98 Trillion Fortune by Outsourcing | Case Study

In the annals of technological innovation, Apple Inc. stands as a testament to what strategic decisions and visionary leadership can achieve. From its humble beginnings in a garage to becoming a three trillion-dollar behemoth, Apple’s success narrative is a tale woven with threads of innovation, design excellence, and a shrewd approach to outsourcing. In this extensive case study, we embark on a journey to dissect the intricate layers of outsourcing strategy to extract valuable lessons for businesses aiming at sustainable growth.

Apple’s evolution is a saga of perpetual reinvention. Founded in 1976 by Steve Jobs, Steve Wozniak, and Ronald Wayne, the company started as a player in the personal computer industry. [ 1 ] Fast forward to the present day, and Apple Inc. has transformed into a global powerhouse, setting industry benchmarks and captivating consumers with its innovative products.

Table of Contents

#1: outsourcing: apple inc.’s manufacturing backbone, a: challenge: scaling up production.

As Apple Inc. ventured into the realm of consumer electronics with products like the iPhone, iPad, and MacBook, the challenge of meeting unprecedented demand emerged. In response, Apple strategically embraced outsourcing, forging key partnerships to tackle this manufacturing conundrum.

Foxconn, also known as Hon Hai Precision Industry Co., Ltd., emerged as Apple’s manufacturing linchpin. With its headquarters in Taiwan, Foxconn became the largest electronics contract manufacturer globally. The statistics tell a compelling story—Foxconn’s revenue in 2021 reached a staggering $214 billion, ranked 20th in the 2023 Fortune Global 500—a significant portion of which was attributed to its collaboration with Apple.

B: Benefit: Cost Savings and Efficiency

The outsourcing strategy wasn’t merely about meeting demand but a calculated move to optimize costs. According to industry reports, the cost of manufacturing an iPhone X was estimated to be around $370, with the device retailing at $999. This exemplifies the cost-effectiveness achieved through outsourcing, particularly with partners like Foxconn, renowned for their efficiency in mass production. In 2023, Apple Inc. launched the titanium-based iPhone 15 Pro Max, manufactured at $558 and currently retailing from $1199 to $1599.

#2: Leveraging Global Talent and Expertise

A: challenge: the pursuit of excellence.

Apple’s commitment to excellence extends beyond its sleek product designs to encompass the entire user experience. To provide this seamless experience, Apple Inc. strategically tapped into a global talent pool, seeking specialized expertise through outsourcing.

Beyond manufacturing, Apple’s collaboration extended to specialized components. For instance, Apple Inc. sourced its A-series chips from Taiwan Semiconductor Manufacturing Company (TSMC), a world leader in semiconductor manufacturing. In 2022, TSMC’s revenue soared to $63 billion, a testament to its pivotal role in Apple’s supply chain.

B: Benefit: Innovation and Quality Assurance

Outsourcing to experts meant that Apple could integrate cutting-edge technology seamlessly. The A-series chips, fabricated by TSMC, consistently pushed the boundaries of performance, ensuring that Apple’s devices were aesthetically pleasing and technological marvels. This collaborative approach contributed to Apple’s reputation for innovation and quality assurance.

#3: The Design Imperative

A: challenge: nurturing creativity.

Apple’s design philosophy is synonymous with elegance and innovation. Outsourcing became a tool to liberate internal resources, allowing Apple’s design team to focus solely on what they do best—creating iconic products.

By outsourcing components and manufacturing, Apple’s in-house design team gained the freedom to innovate without being bogged down by production intricacies. Statistics reveal the impact—Apple’s design-led approach contributed to a brand value of $263.4 billion in 2022, making it the most valuable brand globally.

B: Benefit: Unleashing Creativity

This focus on design resulted in visually stunning products and fostered a culture of innovation within Apple Inc. The iPhone’s iconic design, for instance, not only captured the market but set a new standard for the entire industry. The freedom to innovate became a catalyst for Apple’s success.

#4: Outsourcing in the Digital Age

A: Challenge: Navigating the Digital Landscape

As the digital landscape evolved, Apple Inc. faced the challenge of staying at the forefront of software development. The solution lies in strategic outsourcing partnerships that complement Apple’s internal capabilities.

Apple’s collaboration extended to software development, with partnerships and acquisitions reinforcing its commitment to excellence. For instance, the acquisition of Beats Electronics in 2014 for $3 billion not only bolstered Apple’s presence in the audio industry but also brought the expertise of Beats’ software engineers into the Apple ecosystem.

B: Benefit: Software Synergy

Outsourcing software development allowed Apple to harness the collective expertise of a global talent pool. The collaborative synergy translated into user-friendly interfaces, seamless integration across devices, and a robust app ecosystem. The strategic outsourcing of software development became a key ingredient in Apple’s recipe for success in the digital age.

#5: Ethical Considerations and Corporate Responsibility

A: challenge: balancing success and responsibility.

While the outsourcing strategy contributed significantly to Apple’s success, it also brought attention to ethical considerations and corporate responsibility. Reports of challenging working conditions at some manufacturing partners prompted Apple to reevaluate its approach.

Apple’s response to these ethical concerns showcased adaptability and a commitment to responsible business practices. According to Apple’s Supplier Responsibility Progress Report in 2022, the company conducted over 1,100 supplier assessments, addressing issues related to labor practices, environmental impact, and ethical sourcing.

B: Benefit: Ethical Leadership

Addressing ethical concerns associated with outsourcing elevated Apple’s corporate image. The commitment to responsible business practices resonated with consumers and set a precedent for the industry. This ethical leadership became a crucial element in Apple’s success story.

Final Verdict: The Outsourcing Symphony

In the grand symphony of Apple’s success, outsourcing plays a pivotal role as a harmonious melody that elevates the entire composition. The strategic outsourcing of manufacturing, expertise, design, and software development has propelled Apple to unprecedented heights and is currently worth almost $3 trillion. This in-depth exploration attests to the transformative power of strategic outsourcing.

* Lessons Learned: A Call to Action

1. Strategic Partnerships : Identify and cultivate strategic outsourcing partnerships that align with your business goals and values. Partnering with industry giants like Foxconn and TSMC gave a solid foundation.

2. Focus on Core Competencies : Outsourcing allows you to concentrate on your core competencies, whether design, innovation, or marketing. As exemplified above, streamlining the design process can lead to market-leading products.

3. Global Talent Pool : Tap into a global talent pool to access specialized expertise and stay at the forefront of innovation. Partnerships with global leaders, such as TSMC in semiconductor manufacturing, were proven to be instrumental.

4. Ethical Outsourcing : Prioritize ethical considerations and corporate responsibility in your outsourcing practices to build a positive brand image. As demonstrated above, regular assessments and a commitment to transparency can set industry standards.

5. Adaptability : Be adaptable and responsive to challenges, iterating your outsourcing strategy to meet evolving demands. Responsiveness to ethical concerns showcases the importance of adaptability in sustaining success.

In the business landscape, the outsourcing symphony can be the key to sustained success. As businesses consider their growth strategies, the above case study serves as a compelling testament to the transformative power of strategic outsourcing. Embrace the symphony, conduct it with precision, and let the echoes of success reverberate through the corridors of your organization.

Get in touch with us at CodersOnFire and start outsourcing your software development projects to gain monumental success in your business.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Related Posts

Outsourcing Software Projects Made IBM an Amazing $135 Billion | Case Study

Brought to you by:

Apple in China and India

By: Peter Cohan, Sam Hariharan

The Apple in China and India case explores the competitive challenges faced by a global company in two large emerging markets - China and India. Specifically, in these two large emerging markets,…

- Length: 17 page(s)

- Publication Date: Jul 1, 2020

- Discipline: General Management

- Product #: BAB492-PDF-ENG

What's included:

- Teaching Note

- Educator Copy

$4.95 per student

degree granting course

$8.95 per student

non-degree granting course

Get access to this material, plus much more with a free Educator Account:

- Access to world-famous HBS cases

- Up to 60% off materials for your students

- Resources for teaching online

- Tips and reviews from other Educators

Already registered? Sign in

- Student Registration

- Non-Academic Registration

- Included Materials

The Apple in China and India case explores the competitive challenges faced by a global company in two large emerging markets - China and India. Specifically, in these two large emerging markets, Apple's sales of its flagship iPhone are falling significantly short of its market share in many developed country markets, and well below its own professed and announced revenue and volume targets. The company has to make key strategic decisions regarding its product offerings and the competitive positioning of its products, taking into account the offerings of its key global and local competitors and the unique needs of customers in the two emerging markets in terms of desired product features, and their ability and willingness to pay. In making these choices, Apple has to consider how the decisions made with respect to these two markets align with the broader global strategy for iPhone.

Learning Objectives

1.) Analyzing Global Competition.

2.) Understanding Challenges of Succeeding in Emerging Markt

3) Crafting Global Strategies.

Jul 1, 2020

Discipline:

General Management

Geographies:

China, India, United States

Babson College

BAB492-PDF-ENG

We use cookies to understand how you use our site and to improve your experience, including personalizing content. Learn More . By continuing to use our site, you accept our use of cookies and revised Privacy Policy .

To read this content please select one of the options below:

Please note you do not have access to teaching notes, managing production outsourcing risks in china's apparel industry: a case study of two apparel retailers.

Supply Chain Management

ISSN : 1359-8546

Article publication date: 27 September 2011

This paper aims to examine how Chinese apparel retailers manage their production outsourcing risks and why they elect to manage those risks in a particular manner.

Design/methodology/approach

The investigation used the case study approach to explore factors driving two Chinese apparel retailers operating in different market environments to manage their production outsourcing risks.

The selection of production outsourcing risk management strategies hinges on what apparel retailers view as the most important value their products provide to customers. Product values were linked to specific product characteristics as well as the market environment in which the apparel retailers operated. The retailer that regarded product quality as a key value driver was found to place emphasis on manufacturer selection and use of a formal contract for process control. The retailer that viewed newness and variety as a value driver opted to cultivate a strong, committed business relationship based on Guanxi to achieve speed‐to‐market.

Research limitations/implications

As a case study research, the findings of this study have their limitations in generalisability. Given that one of the retailers did not invoke Guanxi to cultivate a long‐term business relationship with its outsourced manufacturers, the role of Guanxi in outsourcing risk management in China deserves further exploration, as businesses in China become more globalised.

Practical implications/value

This study grounds mainstream outsourcing strategy literature on operational practice through case studies. It highlights the influence of both product characteristics and market environment in dictating the choice of outsourcing risk management strategies in apparel manufacturing.

Originality/value

The study views outsourcing risk management from the perspective of minimizing outsourcing failures, rather than achieving outsourcing success. It reveals that risk management behavior of apparel retailers was linked to the notion of value protection, which varied according to what they considered as their principal product value drivers.

- Outsourcing risks

- Speed‐to‐market

- Value protection

Hon Kam, B. , Chen, L. and Wilding, R. (2011), "Managing production outsourcing risks in China's apparel industry: a case study of two apparel retailers", Supply Chain Management , Vol. 16 No. 6, pp. 428-445. https://doi.org/10.1108/13598541111171147

Emerald Group Publishing Limited

Copyright © 2011, Emerald Group Publishing Limited

Related articles

We’re listening — tell us what you think, something didn’t work….

Report bugs here

All feedback is valuable

Please share your general feedback

Join us on our journey

Platform update page.

Visit emeraldpublishing.com/platformupdate to discover the latest news and updates

Questions & More Information

Answers to the most commonly asked questions here

- News & Analysis on Clinical Trial Services & Contract Research And Development

First oral treatment for chronic kidney disease launched in China by Everest Medicine

14-May-2024 - Last updated on 14-May-2024 at 13:24 GMT

- Email to a friend

This official launch marks a significant advancement in patient care in mainland China, introducing a new era in the treatment of IgA nephropathy (IgAN). IgA nephropathy (IgAN) is a common chronic kidney disease which mainly affects young adults. In IgAN a protein called immunoglobulin A (IgA) becomes trapped in the very fine filters of the kidney (glomeruli), causing damage and scarring to the whole kidney.

China has the highest prevalence of primary glomerular diseases globally, with IgAN accounting for about 35% to 50% of cases. Most IgAN patients risk progressing to end-stage renal disease during their lifetime, often requiring dialysis or kidney transplantation.

Current treatments, like renin-angiotensin system (RAS) inhibitors, fail to address the underlying disease progression, highlighting a significant unmet medical need.

Rogers Yongqing Luo, chief executive officer of Everest Medicines, said the commercialization of Nefecon in the Chinese market represents a significant milestone for Everest and a breakthrough for IgAN patients in China. Nefecon has undergone a 20-year research and development process, becoming the first non-oncology therapeutic to receive Breakthrough Therapy Designation in China by the China National Medical Products Administration (NMPA), and the first treatment for IgAN to receive full approval from the US Food and Drug Administration (FDA).

Five million IgAN patients in China

Professor Zhang Hong is from Peking University First Hospital, a member of the global steering committee for the phase 3 clinical study NefIgArd. He said: “We will actively engage with all stakeholders to improve the accessibility and affordability of this innovative therapy for IgAN. Moreover, we will contribute to improving nephropathy diagnosis, treatment, and disease management, ultimately benefiting more patients. As we advance the commercialization of Nefecon in China and Asia, we will also actively promote the development of other innovative drugs in the nephropathy field, extending benefits to more patients.”

“IgAN is the most common primary glomerular disease, occurring at a young age with a high possibility of progressing to end-stage renal disease. Compared to European and American populations, Chinese IgAN patients experience faster disease progression and poorer prognosis, imposing a heavy burden on patients and society. The full results of the NefIgArd study demonstrate that Nefecon can protect renal function, delay progression to dialysis or kidney transplantation, and significantly reduce urinary protein and hematuria. It is also safe and well-tolerated.”

“Data analysis of the Chinese population shows that Nefecon reduces kidney function decline by 66%, and delays disease progression to dialysis or kidney transplantation by 12.8 years. The approval of Nefecon fills the gap in targeted therapy for IgAN in China, benefiting Chinese patients, improving disease prognosis, and providing clinicians with new treatment options.”

Nefecon - even greater benefit in delaying kidney function decline

The company says the latest analysis, presented at the World Congress of Nephrology 2024, provides further evidence that Nefecon may offer even greater benefit in delaying kidney function decline in Chinese patients with more rapidly progressing disease, without compromising patients' quality of life. Positive results from the global Open Label Extension (OLE) study based on the NefIgArd phase 3 study validated the efficacy and safety of re-treatment with Nefecon independent of prior treatment cycles, providing a solid scientific basis for future long-term maintenance regimens of Nefecon.

"IgAN is highly prevalent in Asia and is one of the main causes of kidney failure in young adults in China. Among IgAN patients, the risk of progressing to end-stage renal disease in Asian populations is 56% higher compared to other populations, and the disease progresses more rapidly, imposing a significant medical burden on patients, families, and society. Therefore, more proactive treatment is needed to intervene and control the risk of disease progression, delaying the need for dialysis or kidney transplantation.

“For a long time, this disease has lacked targeted treatment options, resulting in significant unmet clinical needs," said Professor Xie Jingyuan, chief physician of the Department of Nephrology, Ruijin Hospital affiliated with Shanghai Jiao Tong University School of Medicine.

“Nefecon, as the world's first-in-disease therapy for IgAN, has treated over one hundred patients in total through its early-access program in Boao last April. During the follow-up period, Nefecon was found to be effective in stabilizing renal function, reducing proteinuria and hematuria, and was well tolerated by the patients. It is of great significance for Nefecon to be officially commercialized in mainland China, helping patients with IgAN to initiate treatment as early as possible.”

Nefecon received approval from the China NMPA in November 2023 for the treatment of primary IgAN in adults at risk of disease progression. Additionally, Nefecon has been approved in multiple countries and territories across Europe, the US, and Asia.

Related news

Related products

Saama accelerates data review processes

Content provided by Saama | 25-Mar-2024 | Infographic

In this new infographic, learn how Saama accelerates data review processes. Only Saama has AI/ML models trained for life sciences on over 300 million data...

More Data, More Insights, More Progress

Content provided by Saama | 04-Mar-2024 | Case Study

The sponsor’s clinical development team needed a flexible solution to quickly visualize patient and site data in a single location

Generic method approach for determination of residual solvents in active pharmaceutical ingredients by gas chromatography

Content provided by Almac Group | 29-Nov-2023 | White Paper

Solvents are defined as organic chemicals that are used to dissolve components. They are used during the manufacture of drug substances and can also potentially...

Using Define-XML to build more efficient studies

Content provided by Formedix | 14-Nov-2023 | White Paper

It is commonly thought that Define-XML is simply a dataset descriptor: a way to document what datasets look like, including the names and labels of datasets...

Related suppliers

- Almac Group

- WuXi AppTec

- Saama accelerates data review processes Saama | Download Infographic

- More Data, More Insights, More Progress Saama | Download Case Study

Upcoming editorial webinars

- 12 Jun 2024 Wed Webinar Diversity: Increasing trial inclusivity

On-demand webinars

- How to reduce crosslinking and ensure fast dissolution in soft caps

- Cell and Gene Therapy Manufacturing Webinar

- Innovation in Drug Delivery Webinar

Promotional Features

Outsourcing-Pharma

- Advertise with us

- Why Register?

- Apply to reuse our content